Compression Springs Formula

Definition: Compression spring formulas are the algorithms engineers use to calculate certain compression spring parameters. These formulas were elaborated and corroborated, making it possible to calculate a compression spring design.

The compression spring formulas you are about to see are based on many years of research from the China Spring Products Corp staff. They are what make our compression spring calculator, Spring Creator, such a reliable spring design tool in which you are able to calculate your compression spring’s constant k, working loads, and even some measurements like the length of the wire needed to make one to a thousand springs or the weight of one to a thousand springs. Our spring calculator has it all. You are even able to generate a live blueprint of your compression spring design with the click of a button and email it to yourself or a colleague as well.

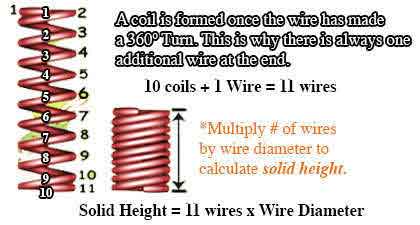

Solid Height Formulas

To calculate solid height (Lsolid) you must add one more wire to the total coils (N) and then multiply the result by the wire diameter (d). In case that your spring has ground ends, you will only need to multiply the wire thickness by the total coils since grinding the ends causes the last coil to only be half the diameter.

Solid Height = Wire Diameter x (Total Coils + 1)

Lsolid = d(N+1)

(if you have ground ends)

Solid Height = Wire Diameter x Total Coils

L solid = dN

Solid Height Diagram

Spring Diameter Formulas

The calculation of your compression spring’s diameters is quite simple. You just have to be able to distinguish which is which. To calculate inner diameter (D inner) you must multiply the wire diameter (d) by two and subtract the result from the outer diameter (D outer). To calculate the outer diameter, you do the opposite; multiply the wire diameter by two and then add the result to the inner diameter. Mean diameter (D) is in between these two values for it is the coil diameter from center of wire to center of wire so in this case you may either subtract one wire diameter from the outer diameter or add one wire diameter to the inner diameter.

Inner Diameter = Outer Diameter – 2 (Wire Diameter)

D inner = D outer – 2d

Outer Diameter = Inner Diameter + 2 (Wire Diameter)

D outer = D inner + 2d

Mean Diameter = Outer Diameter – Wire Diameter

D = D outer – d

OR

Mean Diameter = Inner Diameter + Wire Diameter

D = D inner + d

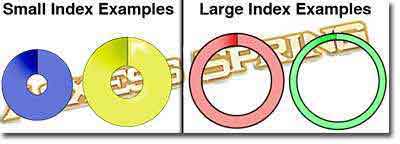

Spring Index Formula

The spring index of your compression spring determines the tightness of your coils as well as the manufacturing difficulty of your spring. To calculate spring index you must divide the mean diameter (D) by the wire diameter (d).

Index = Mean Diameter ÷ Wire Diameter

I = D ÷ d

Large and Small Index

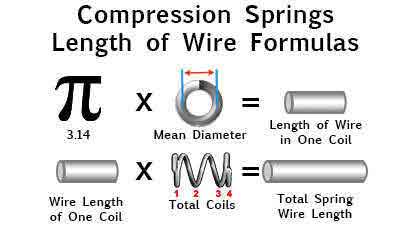

Wire Length Formulas

Calculating the length of your compression spring’s wire will allow you to know how much material is needed in order to manufacture the springs. First, you calculate the wire length of one coil (cL) by multiplying the mean diameter by pi (3.14 or π). Then, to calculate the total compression spring wire length (tL), you must multiply the wire length of one coil (cL) by the total amount of coils (N).

Coil Wire Length = Mean Diameter x Pi

cL = Dπ

Total Wire Length = Coil Wire Length x Total Coils

tL = cL x N

Wire Length Calculation Example

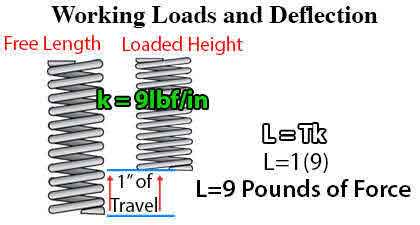

Load and Travel Formulas

The load and travel compression spring formulas provided below are to calculate your working loads. These formulas are very useful to know whether a spring will meet the load and distance traveled you require. To calculate the distance traveled of your spring you must divide the load by the spring rate. On the other hand, to calculate the working loads, you must multiply the distance traveled by the spring rate.

Travel = Load ÷ Rate

T = L ÷ k

Load = Travel x Rate

L = Tk

Working Loads and Deflection Diagram

English

English