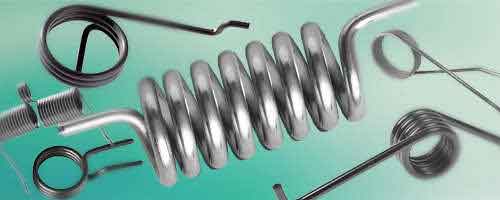

Round Wire Springs

Definition

Round wire springs are objects used to deform under a force/load and return to their original shape once the load/force has been removed.

There are several round wire spring types which are all made up of round wire coils. They collect and release energy in different ways by performing different actions under such loads depending on how they’re made. This consists of the type of body they have, whether the coils are either close wound or open wound, and how their ends are configured.

Torsional Springs

Torsion springs produce torque.

This spring type’s coils wind when one of its legs is pushed by a force meaning their inner diameters contract because their coils are being tightened.

The legs are straight wires coming from one of the spring coils.

They are measured from the center out as shown in our how-to-measure diagrams.

Extension Springs

Tension springs are close wound springs that have hooks on the ends.

The hooks allow for two objects to hang on to the spring and produce a pulling action when a force is applied.

The coils are drawn together by an initially gathered energy called initial tension.

The length of these springs is measured from within the hooks as are the hook lengths.

Similar to measuring a coil’s inner diameter.

Compression Springs

Compress springs are helical springs whose coils have pitch in between them.

These springs have a constant rate of force per inch although there are other types of compression springs which may have variable/non-linear or dual/progressive rates.

The different compression spring types are the following:

English

English