Tolerancias Estándar Para Dimensiones de Resortes y Muelles

En China Spring Products Corp pretendemos fabricar sus resortes y muelles personalizados con precisión, ya que hay ciertas tolerancias estándar de la industria que se deben cumplir. A continuación encontrará una lista de todas las tolerancias estándar de muelles de compresión, muelles de extensión, muelles de torsión, resortes entrelazables, resortes cónicos y resortes de barril.

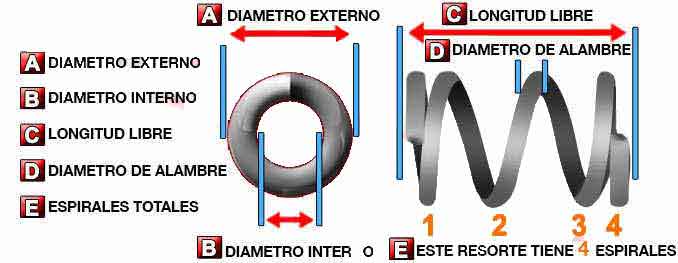

Tolerancias estándar para resortes de compresión:

Tolerancias de Diámetro Externo e Interno

- 0.6350mm a 1.2700mm ± 0.0508mm

- 1.2701mm a 2.5400mm ± 0.0762mm

- 2.5401mm a 6.3500mm ± 0.1270mm

- 6.3501mm a 12.700mm ± 0.2032mm

- 12.701mm a 21.590mm ± 0.3810mm

- 21.591mm a 28.575mm ± 0.5080mm

- 28.576mm a 31.750mm ± 0.6350mm

- 31.751mm a 37.592mm ± 0.7620mm

- 37.593mm a 44.450mm ± 1.0160mm

- 44.451mm a 50.800mm ± 1.3970mm

- 50.801mm a 57.150mm ± 1.6510mm

- 57.151mm a 63.500mm ± 1.9050mm

- 63.501mm a 69.850mm ± 2.2860mm

- 69.851mm a 76.200mm ± 2.9210mm

- 76.201mm a 88.900mm ± 3.3020mm

- 88.901mm a 101.60mm ± 4.0640mm

- 101.61mm a 114.30mm ± 4.8260mm

- 114.31mm a 127.00mm ± 5.7150mm

- 127.01mm a 139.70mm ± 6.3500mm

- 139.71mm a 152.40mm ± 7.1120mm

- 152.41mm a 165.10mm ± 7.8740mm

- 165.11mm a 177.80mm ± 8.8900mm

- 177.81mm a 190.50mm ± 9.7790mm

- 190.51mm a 203.20mm ± 10.541mm

- 203.21mm a 215.90mm ± 11.557mm

- 215.91mm a 228.60mm ± 12.446mm

- 228.61mm a 241.30mm ± 13.335mm

- 241.31mm a 254.00mm ± 14.351mm

Tolerancias de Diámetro de Alambre

Nota: China Spring Products Corp no fabrica el alambre utilizado para fabricar sus resortes.

Las siguientes tolerancias aplican para los siguientes tipos de alambre:

- Hard Drawn HD A679

- Hard Drawn ASTM A227

- Music Wire ASTM A228

- Oil Tempered MB A229

- Carbon Valve A230

- Phosphor Bronze Grade A B159

- Beryllium Copper B197

- Stainless Steel 17-7 ASTM A313

- Stainless Steel 302 ASTM A313

- Stainless Steel 316 ASTM A316

- 0.1270mm a 0.4572mm ± 0.01270mm

- 0.4573mm a 1.0160mm ± 0.01524mm

- 1.0161mm a 1.5875mm ± 0.01778mm

- 1.5876mm a 2.2860mm ± 0.02032mm

- 2.2861mm a 3.1750mm ± 0.02286mm

- 3.1751mm a 6.3500mm ± 0.02540mm

- 6.3501mm a 9.5250mm ± 0.03175mm

- 9.5251mm a 12.700mm ± 0.03493mm

- 12.701mm a 15.875mm ± 0.03810mm

Las siguientes tolerancias aplican para los siguientes tipos de alambre:

- Chrome Silicon A401

- 5160 H

- 2.5400mm a 3.1750mm ± 0.02286mm

- 3.1751mm a 6.3500mm ± 0.02540mm

- 6.3501mm a 9.5250mm ± 0.03175mm

- 9.5251mm a 12.700mm ± 0.03493mm

- 12.701mm a 15.875mm ± 0.03810mm

- 15.876mm a 19.050mm ± 0.04064mm

- 19.051mm a 31.750mm ± 0.04318mm

Tolerancias de Longitud Libre

- 0.0254mm to 12.700mm ± 0.381mm

- 12.701mm to 25.400mm ± 0.508mm

- 25.401mm to 50.800mm ± 1.270mm

- 50.801mm to 101.60mm ± 2.540mm

- 101.61mm to 203.20mm ± 5.080mm

- 203.21mm to 254.00mm ± 7.620mm

- 254.01mm to 381.00mm ± 10.160mm

- 381.01mm to 508.00mm ± 12.700mm

- 508.01mm to 635.00mm ± 16.510mm

- 635.01mm to 762.00mm ± 20.320mm

- 762.01mm to 889.00mm ± 25.400mm

- 889.01mm to 1016.0mm ± 30.480mm

- 1016.1mm to 1219.2mm ± 34.925mm

- 1219.3mm and up ± 38.100mm

Tolerancia de Número de Espirales

±¼ de espiral o hacer referencia si el constante o una fuerza requerida deben ser cumplidas.

Tolerancia de la Longitud Solida

±7% o hacer referencia si el constante o una fuerza requerida deben ser cumplidas.

Tolerancia del Constante (k)

±10%

Tolerancia de la Fuerza / Distancia Recorrida

±10%

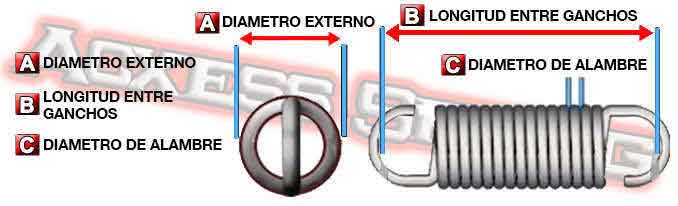

Tolerancias de Diámetro Externo

- 0.6350mm a 1.2700mm ± 0.0508mm

- 1.2701mm a 2.5400mm ± 0.0762mm

- 2.5401mm a 6.3500mm ± 0.1270mm

- 6.3501mm a 12.700mm ± 0.2032mm

- 12.701mm a 21.590mm ± 0.3810mm

- 21.591mm a 28.575mm ± 0.5080mm

- 28.576mm a 31.750mm ± 0.6350mm

- 31.751mm a 37.592mm ± 0.7620mm

- 37.593mm a 44.450mm ± 1.0160mm

- 44.451mm a 50.800mm ± 1.3970mm

- 50.801mm a 57.150mm ± 1.6510mm

- 57.151mm a 63.500mm ± 1.9050mm

- 63.501mm a 69.850mm ± 2.2860mm

- 69.851mm a 76.200mm ± 2.9210mm

- 76.201mm a 88.900mm ± 3.3020mm

- 88.901mm a 101.60mm ± 4.0640mm

- 101.61mm a 114.30mm ± 4.8260mm

- 114.31mm a 127.00mm ± 5.7150mm

- 127.01mm a 139.70mm ± 6.3500mm

- 139.71mm a 152.40mm ± 7.1120mm

- 152.41mm a 165.10mm ± 7.8740mm

- 165.11mm a 177.80mm ± 8.8900mm

Tolerancias de Diámetro de Alambre

Nota: China Spring Products Corp no fabrica el alambre utilizado para fabricar sus resortes.

Las siguientes tolerancias aplican para los siguientes tipos de alambre:

- Hard Drawn HD A679

- Hard Drawn ASTM A227

- Music Wire ASTM A228

- Oil Tempered MB A229

- Carbon Valve A230

- Phosphor Bronze Grade A B159

- Beryllium Copper B197

- Stainless Steel 17-7 ASTM A313

- Stainless Steel 302 ASTM A313

- Stainless Steel 316 ASTM A316

- 0.1270mm a 0.4572mm ± 0.01270mm

- 0.4573mm a 1.0160mm ± 0.01524mm

- 1.0161mm a 1.5875mm ± 0.01778mm

- 1.5876mm a 2.2860mm ± 0.02032mm

- 2.2861mm a 3.1750mm ± 0.02286mm

- 3.1751mm a 6.3500mm ± 0.02540mm

- 6.3501mm a 9.5250mm ± 0.03175mm

- 9.5251mm a 12.700mm ± 0.03493mm

- 12.701mm a 15.875mm ± 0.03810mm

Las siguientes tolerancias aplican para los siguientes tipos de alambre:

- Chrome Silicon A401

- 5160 H

- 2.5400mm a 3.1750mm ± 0.02286mm

- 3.1751mm a 6.3500mm ± 0.02540mm

- 6.3501mm a 9.5250mm ± 0.03175mm

- 9.5251mm a 12.700mm ± 0.03493mm

- 12.701mm a 15.875mm ± 0.03810mm

- 15.876mm a 19.050mm ± 0.04064mm

- 19.051mm a 31.750mm ± 0.04318mm

Tolerancias de Longitud Entre Ganchos

- 0.0254mm a 12.700mm ± 0.381mm

- 12.701mm a 25.400mm ± 0.508mm

- 25.401mm a 50.800mm ± 0.762mm

- 50.801mm a 101.60mm ± 1.270mm

- 101.61mm a 203.20mm ± 2.362mm

- 203.21mm a 254.00mm ± 3.962mm

- 254.01mm a 381.00mm ± 6.250mm

- 381.01mm a 508.00mm ± 8.890mm

- 508.01mm a 635.00mm ± 12.70mm

- 635.01mm a 762.00mm ± 16.51mm

- 762.01mm a 889.00mm ± 20.32mm

- 889.01mm a 1016.0mm ± 25.40mm

- 1016.1mm a 1219.2mm ± 31.75mm

Tolerancia del Constante (k)

±10%

Tolerancia de la Fuerza / Distancia Recorrida

±10%

Tolerancia de Tensión Inicial

Hacer referencia

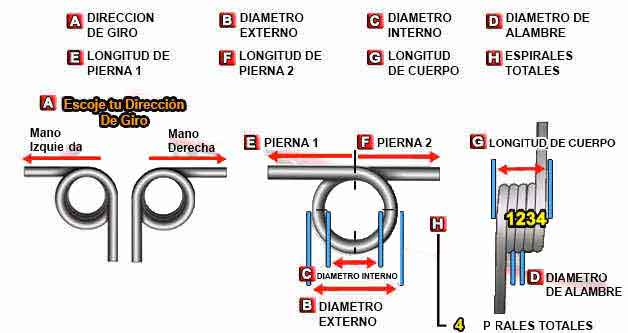

Tolerancias de Diámetro Externo e Interno

- 0.6350mm a 1.2700mm ± 0.0508mm

- 1.2701mm a 2.5400mm ± 0.0762mm

- 2.5401mm a 6.3500mm ± 0.1270mm

- 6.3501mm a 12.700mm ± 0.2032mm

- 12.701mm a 21.590mm ± 0.3810mm

- 21.591mm a 28.575mm ± 0.5080mm

- 28.576mm a 31.750mm ± 0.6350mm

- 31.751mm a 37.592mm ± 0.7620mm

- 37.593mm a 44.450mm ± 1.0160mm

- 44.451mm a 50.800mm ± 1.3970mm

- 50.801mm a 57.150mm ± 1.6510mm

- 57.151mm a 63.500mm ± 1.9050mm

- 63.501mm a 69.850mm ± 2.2860mm

- 69.851mm a 76.200mm ± 2.9210mm

- 76.201mm a 88.900mm ± 3.3020mm

- 88.901mm a 101.60mm ± 4.0640mm

- 101.61mm a 114.30mm ± 4.8260mm

- 114.31mm a 127.00mm ± 5.7150mm

- 127.01mm a 139.70mm ± 6.3500mm

- 139.71mm a 152.40mm ± 7.1120mm

- 152.41mm a 165.10mm ± 7.8740mm

- 165.11mm a 177.80mm ± 8.8900mm

- 177.81mm a 190.50mm ± 9.7790mm

- 190.51mm a 203.20mm ± 10.541mm

- 203.21mm a 215.90mm ± 11.557mm

- 215.91mm a 228.60mm ± 12.446mm

- 228.61mm a 241.30mm ± 13.335mm

- 241.31mm a 254.00mm ± 14.351mm

Tolerancias de Diámetro de Alambre

Nota: China Spring Products Corp no fabrica el alambre utilizado para fabricar sus resortes.

Las siguientes tolerancias aplican para los siguientes tipos de alambre:

- Hard Drawn HD A679

- Hard Drawn ASTM A227

- Music Wire ASTM A228

- Oil Tempered MB A229

- Carbon Valve A230

- Phosphor Bronze Grade A B159

- Beryllium Copper B197

- Stainless Steel 17-7 ASTM A313

- Stainless Steel 302 ASTM A313

- Stainless Steel 316 ASTM A316

- 0.1270mm a 0.4572mm ± 0.01270mm

- 0.4573mm a 1.0160mm ± 0.01524mm

- 1.0161mm a 1.5875mm ± 0.01778mm

- 1.5876mm a 2.2860mm ± 0.02032mm

- 2.2861mm a 3.1750mm ± 0.02286mm

- 3.1751mm a 6.3500mm ± 0.02540mm

- 6.3501mm a 9.5250mm ± 0.03175mm

- 9.5251mm a 12.700mm ± 0.03493mm

- 12.701mm a 15.875mm ± 0.03810mm

Las siguientes tolerancias aplican para los siguientes tipos de alambre:

- Chrome Silicon A401

- 5160 H

- 2.5400mm a 3.1750mm ± 0.02286mm

- 3.1751mm a 6.3500mm ± 0.02540mm

- 6.3501mm a 9.5250mm ± 0.03175mm

- 9.5251mm a 12.700mm ± 0.03493mm

- 12.701mm a 15.875mm ± 0.03810mm

- 15.876mm a 19.050mm ± 0.04064mm

- 19.051mm a 31.750mm ± 0.04318mm

Tolerancia de Longitud de las Piernas

- 0.508mm a 1.270mm ± 0.254mm

- 1.271mm a 6.350mm ± 0.635mm

- 6.351mm a 25.40mm ± 0.889mm

- 25.41mm a 50.80mm ± 1.270mm

- 50.81mm a 101.6mm ± 2.032mm

- 101.7mm a 190.5mm ± 3.810mm

- 190.6mm a 254.0mm ± 6.985mm

Tolerancia de Número de Espirales / Posición Libre

±3/16 de un espiral

Tolerancia del Constante (k)

S±10%

Tolerancia del Torque

±10%

Diámetro exterior / interior pequeño y grande

- 0.6350mm a 1.2700mm ± 0.0508mm

- 1.2701mm a 2.5400mm ± 0.0762mm

- 2.5401mm a 6.3500mm ± 0.1270mm

- 6.3501mm a 12.700mm ± 0.2032mm

- 12.701mm a 21.590mm ± 0.3810mm

- 21.591mm a 28.575mm ± 0.5080mm

- 28.576mm a 31.750mm ± 0.6350mm

- 31.751mm a 37.592mm ± 0.7620mm

- 37.593mm a 44.450mm ± 1.0160mm

- 44.451mm a 50.800mm ± 1.3970mm

- 50.801mm a 57.150mm ± 1.6510mm

- 57.151mm a 63.500mm ± 1.9050mm

- 63.501mm a 69.850mm ± 2.2860mm

- 69.851mm a 76.200mm ± 2.9210mm

- 76.201mm a 88.900mm ± 3.3020mm

- 88.901mm a 101.60mm ± 4.0640mm

- 101.61mm a 114.30mm ± 4.8260mm

Tolerancias de Diámetro de Alambre

Nota: China Spring Products Corp no fabrica el alambre utilizado para fabricar sus resortes.

Las siguientes tolerancias aplican para los siguientes tipos de alambre:

- Hard Drawn HD A679

- Hard Drawn ASTM A227

- Music Wire ASTM A228

- Oil Tempered MB A229

- Carbon Valve A230

- Phosphor Bronze Grade A B159

- Beryllium Copper B197

- Stainless Steel 17-7 ASTM A313

- Stainless Steel 302 ASTM A313

- Stainless Steel 316 ASTM A316

- 0.1270mm a 0.4572mm ± 0.01270mm

- 0.4573mm a 1.0160mm ± 0.01524mm

- 1.0161mm a 1.5875mm ± 0.01778mm

- 1.5876mm a 2.2860mm ± 0.02032mm

- 2.2861mm a 3.1750mm ± 0.02286mm

- 3.1751mm a 6.3500mm ± 0.02540mm

- 6.3501mm a 9.5250mm ± 0.03175mm

- 9.5251mm a 12.700mm ± 0.03493mm

- 12.701mm a 15.875mm ± 0.03810mm

Las siguientes tolerancias aplican para los siguientes tipos de alambre:

- Chrome Silicon A401

- 5160 H

- 2.5400mm a 3.1750mm ± 0.02286mm

- 3.1751mm a 6.3500mm ± 0.02540mm

- 6.3501mm a 9.5250mm ± 0.03175mm

- 9.5251mm a 12.700mm ± 0.03493mm

- 12.701mm a 15.875mm ± 0.03810mm

- 15.876mm a 19.050mm ± 0.04064mm

- 19.051mm a 31.750mm ± 0.04318mm

Tolerancias de Longitud Libre

- 0.0254mm a 12.700mm ± 0.381mm

- 12.701mm a 25.400mm ± 0.508mm

- 25.401mm a 50.800mm ± 0.762mm

- 50.801mm a 101.60mm ± 1.270mm

- 101.61mm a 203.20mm ± 2.362mm

- 203.21mm a 254.00mm ± 3.962mm

- 254.01mm a 381.00mm ± 6.250mm

- 381.01mm a 508.00mm ± 8.890mm

- 508.01mm a 635.00mm ± 12.70mm

- 635.01mm a 762.00mm ± 16.51mm

- 762.01mm a 889.00mm ± 20.32mm

- 889.01mm a 1016.0mm ± 25.40mm

- 1016.1mm a 1219.2mm ± 31.75mm

Tolerancia de Número de Espirales

±¼ de espiral o hacer referencia si el constante o una fuerza requerida deben ser cumplidas.

Tolerancia de la Fuerza / Distancia Recorrida

±10%

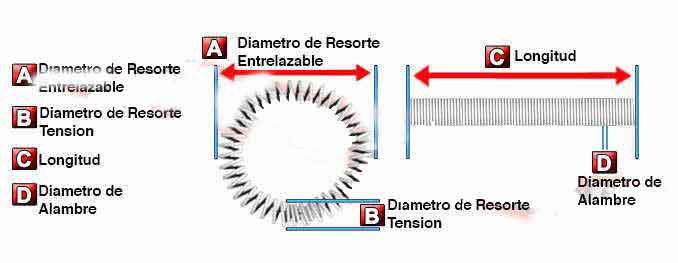

Tolerancias de Diámetro Externo del Resorte de Tensión

- 0.6350mm a 1.2700mm ± 0.0508mm

- 1.2701mm a 2.5400mm ± 0.0762mm

- 2.5401mm a 6.3500mm ± 0.1270mm

- 6.3501mm a 12.700mm ± 0.2032mm

- 12.701mm a 21.590mm ± 0.3810mm

- 21.591mm a 28.575mm ± 0.5080mm

- 28.576mm a 31.750mm ± 0.6350mm

- 31.751mm a 37.592mm ± 0.7620mm

- 37.593mm a 44.450mm ± 1.0160mm

- 44.451mm a 50.800mm ± 1.3970mm

- 50.801mm a 57.150mm ± 1.6510mm

- 57.151mm a 63.500mm ± 1.9050mm

- 63.501mm a 69.850mm ± 2.2860mm

- 69.851mm a 76.200mm ± 2.9210mm

- 76.201mm a 88.900mm ± 3.3020mm

- 88.901mm a 101.60mm ± 4.0640mm

- 101.61mm a 114.30mm ± 4.8260mm

- 114.31mm a 127.00mm ± 5.7150mm

- 127.01mm a 139.70mm ± 6.3500mm

- 139.71mm a 152.40mm ± 7.1120mm

- 152.41mm a 165.10mm ± 7.8740mm

- 165.11mm a 177.80mm ± 8.8900mm

Tolerancias de Diámetro Externo del Resorte Entrelazable

- 76.20mm a 127.0mm ± 6.350mm

- 127.1mm a 190.5mm ± 9.525mm

- 190.6mm a 254.0mm ± 12.70mm

- 254.1mm a 317.5mm ± 19.05mm

- 317.6mm a 381.0mm ± 22.23mm

- 381.1mm a 508.0mm ± 25.40mm

- 508.1mm a 635.0mm ± 31.75mm

- 635.1mm a 762.0mm ± 38.10mm

Tolerancias de Longitud

- 0.0254mm a 12.700mm ± 0.381mm

- 12.701mm a 25.400mm ± 0.508mm

- 25.401mm a 50.800mm ± 0.762mm

- 50.801mm a 101.60mm ± 1.270mm

- 101.61mm a 203.20mm ± 2.362mm

- 203.21mm a 254.00mm ± 3.962mm

- 254.01mm a 381.00mm ± 6.250mm

- 381.01mm a 508.00mm ± 8.890mm

- 508.01mm a 635.00mm ± 12.70mm

- 635.01mm a 762.00mm ± 16.51mm

- 762.01mm a 889.00mm ± 20.32mm

- 889.01mm a 1016.0mm ± 25.40mm

- 1016.1mm a 1219.2mm ± 31.75mm

Tolerancia del Constante (k)

±10%

Tolerancia de Diámetro de alambre

Nota: China Spring Products Corp no fabrica el alambre utilizado para fabricar sus resortes.

Las siguientes tolerancias aplican para los siguientes tipos de alambre:

- Hard Drawn HD A679

- Hard Drawn ASTM A227

- Music Wire ASTM A228

- Oil Tempered MB A229

- Carbon Valve A230

- Phosphor Bronze Grade A B159

- Beryllium Copper B197

- Stainless Steel 17-7 ASTM A313

- Stainless Steel 302 ASTM A313

- Stainless Steel 316 ASTM A316

- 0.005” a 0.018” ± 0.0005”

- 0.019” a 0.040” ± 0.0006”

- 0.041” a 0.0625” ± 0.0007”

- 0.063” a 0.090” ± 0.0008”

- 0.091” a 0.125” ± 0.0009”

- 0.126” a 0.250” ± 0.001”

- 0.251” a 0.375” ± 0.00125”

- 0.376” a 0.500” ± 0.001375”

- 0.501” a 0.625” ± 0.0015”

Las siguientes tolerancias aplican para los siguientes tipos de alambre:

- Chrome Silicon A401

- 5160 H

- 0.100” a 0.125” ± 0.0009”

- 0.126” a 0.250” ± 0.001”

- 0.251” a 0.375” ± 0.00125”

- 0.376” a 0.500” ± 0.001375”

- 0.501” a 0.625” ± 0.0015”

- 0.626” a 0.750” ± 0.0016”

- 0.751” a 1.250” ± 0.0017”

English

English