Compression Springs Nomenclature

Definition: Compression springs are helically coiled round wires shaped with pitch in between each coil. They are used to store energy when compressed and to release that energy when a load is released.

Note: Click on the highlighted titles to learn more.

Helical Spring

The cylindrical shape of a compression spring due to the three-dimensional form of its round/circular coils.

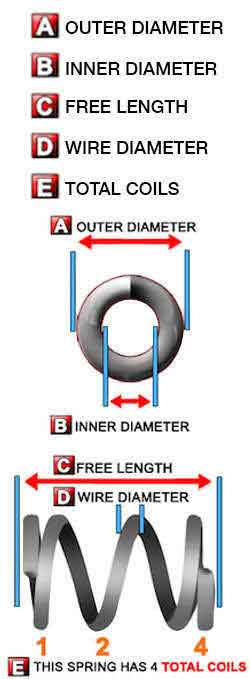

Wire Diameter

The thickness of the round wire which the compression spring is made of.

Outer Diameter

The thickness of the coils that form the compression spring’s body.

Inner Diameter

The width of the inside of the coils. Calculate by subtracting two wire diameters from the outer diameter.

Mean Diameter

The medium or intermediate diameter that is located right in the middle of inner diameter and outer diameter. Calculate by subtracting one wire diameter from the outer diameter or by adding one wire diameter to the inner diameter.

Free Length

The free, unloaded length of a compression spring.

Total Coils

The total amount of coils including open and closed coils.

Active Coils

The active amount of coils including only open coils with pitch in between them.

Pitch

The distance between your spring’s coils.

Rise Angle of Coils

Because there is pitch in between the coils, the wire which the coils are made of rises. This is the measurement of how much the coil is raised.

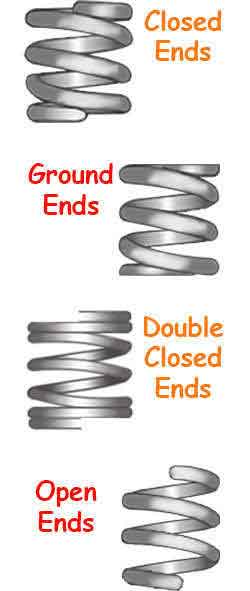

Closed Ends (Squared Ends)

Closed coils without any pitch in it at the edges of the compression springs. (first and/or last coils)

Closed and Ground Ends (Squared and Ground)

Closed coils without any pitch in it at the edges of the compression springs which are ground to help the spring stand straight on a flat surface. (first and/or last coils)

Double Closed Ends

Two closed coils without any pitch in it at the edges of the compression springs. (first and/or last coils)

Open Ends

All coils of the spring have pitch in between them, including the edges.

Solid Height

The length/height of your compression spring when it is fully compressed and all of the coils are touching. You calculate this value by multiplying the wire diameter by the total coils and adding one more wire diameter. In the case that your compression spring may have ground ends, you will only multiply the total coils by the wire diameter.

Index

The proportional ratio between your spring’s wire diameter and mean diameter. It specifies the tightness of your compression spring’s coils.

Rate

The constant amount of force it takes your spring to travel one unit of measurement. (Load is proportional to displacement/deflection)

Loaded Height

The compressed length/height of your spring when a load has been placed on it.

Travel (Deflection)

The motion in which a spring is compressed. The distance traveled is the difference between the free length and the loaded height.

Load (Force)

The force being applied on the spring in order for it to travel.

Maximum Travel Considering Loaded Height

The maximum travel of your compression spring considering its solid height as to not exceed it.

Maximum Load Considering Loaded Height

The maximum load of your compression spring considering its solid height as to not exceed it.

True Maximum Travel

The travel you might be able to achieve out of your spring if you were to make the free length longer. To calculate how much you are able to increase the free length, subtract the “Max F” from the “True Max F”; the result will show you how much free length you’ll be able to add to the compression spring. If this value is equal to the maximum travel considering solid height, you will not be able to add any more travel.

True Maximum Load

The load you could be able to get out of your compression spring if you increased the free length. To calculate how much longer your free length can be, subtract the “Max F” from the “True Max F” and add anything less than or equal to the result to get more load out of your spring. If this value is equal to the maximum load considering solid height, you will not be able to add any more free length.

Endurance Limit

Maximum stress at which your compression spring will perform indefinitely without failure for a given minimum stress limit.

Slenderness Ratio/Buckling

The action of a compression spring bending to the side after being compressed due to having a long free length in proportion to its mean diameter.

Permanent Set

The product of exceeding the elastic properties of a compression spring thus keeping it from returning to its original free length once the load has been released.

The cylindrical shape of a compression spring due to the three-dimensional form of its round/circular coils.

The thickness of the round wire which the compression spring is made of.

Outer Diameter

The thickness of the coils that form the compression spring’s body.

Inner Diameter

The width of the inside of the coils. Calculate by subtracting two wire diameters from the outer diameter.

Mean Diameter

The medium or intermediate diameter that is located right in the middle of inner diameter and outer diameter. Calculate by subtracting one wire diameter from the outer diameter or by adding one wire diameter to the inner diameter.

Free Length

The free, unloaded length of a compression spring.

Total Coils

The total amount of coils including open and closed coils.

Active Coils

The active amount of coils including only open coils with pitch in between them.

Pitch

The distance between your spring’s coils.

Rise Angle of Coils

Because there is pitch in between the coils, the wire which the coils are made of rises. This is the measurement of how much the coil is raised.

Closed Ends (Squared Ends)

Closed coils without any pitch in it at the edges of the compression springs. (first and/or last coils)

Closed and Ground Ends (Squared and Ground)

Closed coils without any pitch in it at the edges of the compression springs which are ground to help the spring stand straight on a flat surface. (first and/or last coils)

Double Closed Ends

Two closed coils without any pitch in it at the edges of the compression springs. (first and/or last coils)

Open Ends

All coils of the spring have pitch in between them, including the edges.

Solid Height

The length/height of your compression spring when it is fully compressed and all of the coils are touching. You calculate this value by multiplying the wire diameter by the total coils and adding one more wire diameter. In the case that your compression spring may have ground ends, you will only multiply the total coils by the wire diameter.

Index

The proportional ratio between your spring’s wire diameter and mean diameter. It specifies the tightness of your compression spring’s coils.

Rate

The constant amount of force it takes your spring to travel one unit of measurement. (Load is proportional to displacement/deflection)

Loaded Height

The compressed length/height of your spring when a load has been placed on it.

Travel (Deflection)

The motion in which a spring is compressed. The distance traveled is the difference between the free length and the loaded height.

Load (Force)

The force being applied on the spring in order for it to travel.

Maximum Travel Considering Loaded Height

The maximum travel of your compression spring considering its solid height as to not exceed it.

Maximum Load Considering Loaded Height

The maximum load of your compression spring considering its solid height as to not exceed it.

True Maximum Travel

The travel you might be able to achieve out of your spring if you were to make the free length longer. To calculate how much you are able to increase the free length, subtract the “Max F” from the “True Max F”; the result will show you how much free length you’ll be able to add to the compression spring. If this value is equal to the maximum travel considering solid height, you will not be able to add any more travel.

True Maximum Load

The load you could be able to get out of your compression spring if you increased the free length. To calculate how much longer your free length can be, subtract the “Max F” from the “True Max F” and add anything less than or equal to the result to get more load out of your spring. If this value is equal to the maximum load considering solid height, you will not be able to add any more free length.

Endurance Limit

Maximum stress at which your compression spring will perform indefinitely without failure for a given minimum stress limit.

Slenderness Ratio/Buckling

The action of a compression spring bending to the side after being compressed due to having a long free length in proportion to its mean diameter.

Permanent Set

The product of exceeding the elastic properties of a compression spring thus keeping it from returning to its original free length once the load has been released.

The thickness of the coils that form the compression spring’s body.

The width of the inside of the coils. Calculate by subtracting two wire diameters from the outer diameter.

Mean Diameter

The medium or intermediate diameter that is located right in the middle of inner diameter and outer diameter. Calculate by subtracting one wire diameter from the outer diameter or by adding one wire diameter to the inner diameter.

Free Length

The free, unloaded length of a compression spring.

Total Coils

The total amount of coils including open and closed coils.

Active Coils

The active amount of coils including only open coils with pitch in between them.

Pitch

The distance between your spring’s coils.

Rise Angle of Coils

Because there is pitch in between the coils, the wire which the coils are made of rises. This is the measurement of how much the coil is raised.

Closed Ends (Squared Ends)

Closed coils without any pitch in it at the edges of the compression springs. (first and/or last coils)

Closed and Ground Ends (Squared and Ground)

Closed coils without any pitch in it at the edges of the compression springs which are ground to help the spring stand straight on a flat surface. (first and/or last coils)

Double Closed Ends

Two closed coils without any pitch in it at the edges of the compression springs. (first and/or last coils)

Open Ends

All coils of the spring have pitch in between them, including the edges.

Solid Height

The length/height of your compression spring when it is fully compressed and all of the coils are touching. You calculate this value by multiplying the wire diameter by the total coils and adding one more wire diameter. In the case that your compression spring may have ground ends, you will only multiply the total coils by the wire diameter.

Index

The proportional ratio between your spring’s wire diameter and mean diameter. It specifies the tightness of your compression spring’s coils.

Rate

The constant amount of force it takes your spring to travel one unit of measurement. (Load is proportional to displacement/deflection)

Loaded Height

The compressed length/height of your spring when a load has been placed on it.

Travel (Deflection)

The motion in which a spring is compressed. The distance traveled is the difference between the free length and the loaded height.

Load (Force)

The force being applied on the spring in order for it to travel.

Maximum Travel Considering Loaded Height

The maximum travel of your compression spring considering its solid height as to not exceed it.

Maximum Load Considering Loaded Height

The maximum load of your compression spring considering its solid height as to not exceed it.

True Maximum Travel

The travel you might be able to achieve out of your spring if you were to make the free length longer. To calculate how much you are able to increase the free length, subtract the “Max F” from the “True Max F”; the result will show you how much free length you’ll be able to add to the compression spring. If this value is equal to the maximum travel considering solid height, you will not be able to add any more travel.

True Maximum Load

The load you could be able to get out of your compression spring if you increased the free length. To calculate how much longer your free length can be, subtract the “Max F” from the “True Max F” and add anything less than or equal to the result to get more load out of your spring. If this value is equal to the maximum load considering solid height, you will not be able to add any more free length.

Endurance Limit

Maximum stress at which your compression spring will perform indefinitely without failure for a given minimum stress limit.

Slenderness Ratio/Buckling

The action of a compression spring bending to the side after being compressed due to having a long free length in proportion to its mean diameter.

Permanent Set

The product of exceeding the elastic properties of a compression spring thus keeping it from returning to its original free length once the load has been released.

The medium or intermediate diameter that is located right in the middle of inner diameter and outer diameter. Calculate by subtracting one wire diameter from the outer diameter or by adding one wire diameter to the inner diameter.

The free, unloaded length of a compression spring.

Total Coils

The total amount of coils including open and closed coils.

Active Coils

The active amount of coils including only open coils with pitch in between them.

Pitch

The distance between your spring’s coils.

Rise Angle of Coils

Because there is pitch in between the coils, the wire which the coils are made of rises. This is the measurement of how much the coil is raised.

Closed Ends (Squared Ends)

Closed coils without any pitch in it at the edges of the compression springs. (first and/or last coils)

Closed and Ground Ends (Squared and Ground)

Closed coils without any pitch in it at the edges of the compression springs which are ground to help the spring stand straight on a flat surface. (first and/or last coils)

Double Closed Ends

Two closed coils without any pitch in it at the edges of the compression springs. (first and/or last coils)

Open Ends

All coils of the spring have pitch in between them, including the edges.

Solid Height

The length/height of your compression spring when it is fully compressed and all of the coils are touching. You calculate this value by multiplying the wire diameter by the total coils and adding one more wire diameter. In the case that your compression spring may have ground ends, you will only multiply the total coils by the wire diameter.

Index

The proportional ratio between your spring’s wire diameter and mean diameter. It specifies the tightness of your compression spring’s coils.

Rate

The constant amount of force it takes your spring to travel one unit of measurement. (Load is proportional to displacement/deflection)

Loaded Height

The compressed length/height of your spring when a load has been placed on it.

Travel (Deflection)

The motion in which a spring is compressed. The distance traveled is the difference between the free length and the loaded height.

Load (Force)

The force being applied on the spring in order for it to travel.

Maximum Travel Considering Loaded Height

The maximum travel of your compression spring considering its solid height as to not exceed it.

Maximum Load Considering Loaded Height

The maximum load of your compression spring considering its solid height as to not exceed it.

True Maximum Travel

The travel you might be able to achieve out of your spring if you were to make the free length longer. To calculate how much you are able to increase the free length, subtract the “Max F” from the “True Max F”; the result will show you how much free length you’ll be able to add to the compression spring. If this value is equal to the maximum travel considering solid height, you will not be able to add any more travel.

True Maximum Load

The load you could be able to get out of your compression spring if you increased the free length. To calculate how much longer your free length can be, subtract the “Max F” from the “True Max F” and add anything less than or equal to the result to get more load out of your spring. If this value is equal to the maximum load considering solid height, you will not be able to add any more free length.

Endurance Limit

Maximum stress at which your compression spring will perform indefinitely without failure for a given minimum stress limit.

Slenderness Ratio/Buckling

The action of a compression spring bending to the side after being compressed due to having a long free length in proportion to its mean diameter.

Permanent Set

The product of exceeding the elastic properties of a compression spring thus keeping it from returning to its original free length once the load has been released.

The total amount of coils including open and closed coils.

The active amount of coils including only open coils with pitch in between them.

Pitch

The distance between your spring’s coils.

Rise Angle of Coils

Because there is pitch in between the coils, the wire which the coils are made of rises. This is the measurement of how much the coil is raised.

Closed Ends (Squared Ends)

Closed coils without any pitch in it at the edges of the compression springs. (first and/or last coils)

Closed and Ground Ends (Squared and Ground)

Closed coils without any pitch in it at the edges of the compression springs which are ground to help the spring stand straight on a flat surface. (first and/or last coils)

Double Closed Ends

Two closed coils without any pitch in it at the edges of the compression springs. (first and/or last coils)

Open Ends

All coils of the spring have pitch in between them, including the edges.

Solid Height

The length/height of your compression spring when it is fully compressed and all of the coils are touching. You calculate this value by multiplying the wire diameter by the total coils and adding one more wire diameter. In the case that your compression spring may have ground ends, you will only multiply the total coils by the wire diameter.

Index

The proportional ratio between your spring’s wire diameter and mean diameter. It specifies the tightness of your compression spring’s coils.

Rate

The constant amount of force it takes your spring to travel one unit of measurement. (Load is proportional to displacement/deflection)

Loaded Height

The compressed length/height of your spring when a load has been placed on it.

Travel (Deflection)

The motion in which a spring is compressed. The distance traveled is the difference between the free length and the loaded height.

Load (Force)

The force being applied on the spring in order for it to travel.

Maximum Travel Considering Loaded Height

The maximum travel of your compression spring considering its solid height as to not exceed it.

Maximum Load Considering Loaded Height

The maximum load of your compression spring considering its solid height as to not exceed it.

True Maximum Travel

The travel you might be able to achieve out of your spring if you were to make the free length longer. To calculate how much you are able to increase the free length, subtract the “Max F” from the “True Max F”; the result will show you how much free length you’ll be able to add to the compression spring. If this value is equal to the maximum travel considering solid height, you will not be able to add any more travel.

True Maximum Load

The load you could be able to get out of your compression spring if you increased the free length. To calculate how much longer your free length can be, subtract the “Max F” from the “True Max F” and add anything less than or equal to the result to get more load out of your spring. If this value is equal to the maximum load considering solid height, you will not be able to add any more free length.

Endurance Limit

Maximum stress at which your compression spring will perform indefinitely without failure for a given minimum stress limit.

Slenderness Ratio/Buckling

The action of a compression spring bending to the side after being compressed due to having a long free length in proportion to its mean diameter.

Permanent Set

The product of exceeding the elastic properties of a compression spring thus keeping it from returning to its original free length once the load has been released.

The distance between your spring’s coils.

Because there is pitch in between the coils, the wire which the coils are made of rises. This is the measurement of how much the coil is raised.

Closed Ends (Squared Ends)

Closed coils without any pitch in it at the edges of the compression springs. (first and/or last coils)

Closed and Ground Ends (Squared and Ground)

Closed coils without any pitch in it at the edges of the compression springs which are ground to help the spring stand straight on a flat surface. (first and/or last coils)

Double Closed Ends

Two closed coils without any pitch in it at the edges of the compression springs. (first and/or last coils)

Open Ends

All coils of the spring have pitch in between them, including the edges.

Solid Height

The length/height of your compression spring when it is fully compressed and all of the coils are touching. You calculate this value by multiplying the wire diameter by the total coils and adding one more wire diameter. In the case that your compression spring may have ground ends, you will only multiply the total coils by the wire diameter.

Index

The proportional ratio between your spring’s wire diameter and mean diameter. It specifies the tightness of your compression spring’s coils.

Rate

The constant amount of force it takes your spring to travel one unit of measurement. (Load is proportional to displacement/deflection)

Loaded Height

The compressed length/height of your spring when a load has been placed on it.

Travel (Deflection)

The motion in which a spring is compressed. The distance traveled is the difference between the free length and the loaded height.

Load (Force)

The force being applied on the spring in order for it to travel.

Maximum Travel Considering Loaded Height

The maximum travel of your compression spring considering its solid height as to not exceed it.

Maximum Load Considering Loaded Height

The maximum load of your compression spring considering its solid height as to not exceed it.

True Maximum Travel

The travel you might be able to achieve out of your spring if you were to make the free length longer. To calculate how much you are able to increase the free length, subtract the “Max F” from the “True Max F”; the result will show you how much free length you’ll be able to add to the compression spring. If this value is equal to the maximum travel considering solid height, you will not be able to add any more travel.

True Maximum Load

The load you could be able to get out of your compression spring if you increased the free length. To calculate how much longer your free length can be, subtract the “Max F” from the “True Max F” and add anything less than or equal to the result to get more load out of your spring. If this value is equal to the maximum load considering solid height, you will not be able to add any more free length.

Endurance Limit

Maximum stress at which your compression spring will perform indefinitely without failure for a given minimum stress limit.

Slenderness Ratio/Buckling

The action of a compression spring bending to the side after being compressed due to having a long free length in proportion to its mean diameter.

Permanent Set

The product of exceeding the elastic properties of a compression spring thus keeping it from returning to its original free length once the load has been released.

Closed coils without any pitch in it at the edges of the compression springs. (first and/or last coils)

Closed coils without any pitch in it at the edges of the compression springs which are ground to help the spring stand straight on a flat surface. (first and/or last coils)

Double Closed Ends

Two closed coils without any pitch in it at the edges of the compression springs. (first and/or last coils)

Open Ends

All coils of the spring have pitch in between them, including the edges.

Solid Height

The length/height of your compression spring when it is fully compressed and all of the coils are touching. You calculate this value by multiplying the wire diameter by the total coils and adding one more wire diameter. In the case that your compression spring may have ground ends, you will only multiply the total coils by the wire diameter.

Index

The proportional ratio between your spring’s wire diameter and mean diameter. It specifies the tightness of your compression spring’s coils.

Rate

The constant amount of force it takes your spring to travel one unit of measurement. (Load is proportional to displacement/deflection)

Loaded Height

The compressed length/height of your spring when a load has been placed on it.

Travel (Deflection)

The motion in which a spring is compressed. The distance traveled is the difference between the free length and the loaded height.

Load (Force)

The force being applied on the spring in order for it to travel.

Maximum Travel Considering Loaded Height

The maximum travel of your compression spring considering its solid height as to not exceed it.

Maximum Load Considering Loaded Height

The maximum load of your compression spring considering its solid height as to not exceed it.

True Maximum Travel

The travel you might be able to achieve out of your spring if you were to make the free length longer. To calculate how much you are able to increase the free length, subtract the “Max F” from the “True Max F”; the result will show you how much free length you’ll be able to add to the compression spring. If this value is equal to the maximum travel considering solid height, you will not be able to add any more travel.

True Maximum Load

The load you could be able to get out of your compression spring if you increased the free length. To calculate how much longer your free length can be, subtract the “Max F” from the “True Max F” and add anything less than or equal to the result to get more load out of your spring. If this value is equal to the maximum load considering solid height, you will not be able to add any more free length.

Endurance Limit

Maximum stress at which your compression spring will perform indefinitely without failure for a given minimum stress limit.

Slenderness Ratio/Buckling

The action of a compression spring bending to the side after being compressed due to having a long free length in proportion to its mean diameter.

Permanent Set

The product of exceeding the elastic properties of a compression spring thus keeping it from returning to its original free length once the load has been released.

Two closed coils without any pitch in it at the edges of the compression springs. (first and/or last coils)

All coils of the spring have pitch in between them, including the edges.

Solid Height

The length/height of your compression spring when it is fully compressed and all of the coils are touching. You calculate this value by multiplying the wire diameter by the total coils and adding one more wire diameter. In the case that your compression spring may have ground ends, you will only multiply the total coils by the wire diameter.

Index

The proportional ratio between your spring’s wire diameter and mean diameter. It specifies the tightness of your compression spring’s coils.

Rate

The constant amount of force it takes your spring to travel one unit of measurement. (Load is proportional to displacement/deflection)

Loaded Height

The compressed length/height of your spring when a load has been placed on it.

Travel (Deflection)

The motion in which a spring is compressed. The distance traveled is the difference between the free length and the loaded height.

Load (Force)

The force being applied on the spring in order for it to travel.

Maximum Travel Considering Loaded Height

The maximum travel of your compression spring considering its solid height as to not exceed it.

Maximum Load Considering Loaded Height

The maximum load of your compression spring considering its solid height as to not exceed it.

True Maximum Travel

The travel you might be able to achieve out of your spring if you were to make the free length longer. To calculate how much you are able to increase the free length, subtract the “Max F” from the “True Max F”; the result will show you how much free length you’ll be able to add to the compression spring. If this value is equal to the maximum travel considering solid height, you will not be able to add any more travel.

True Maximum Load

The load you could be able to get out of your compression spring if you increased the free length. To calculate how much longer your free length can be, subtract the “Max F” from the “True Max F” and add anything less than or equal to the result to get more load out of your spring. If this value is equal to the maximum load considering solid height, you will not be able to add any more free length.

Endurance Limit

Maximum stress at which your compression spring will perform indefinitely without failure for a given minimum stress limit.

Slenderness Ratio/Buckling

The action of a compression spring bending to the side after being compressed due to having a long free length in proportion to its mean diameter.

Permanent Set

The product of exceeding the elastic properties of a compression spring thus keeping it from returning to its original free length once the load has been released.

The length/height of your compression spring when it is fully compressed and all of the coils are touching. You calculate this value by multiplying the wire diameter by the total coils and adding one more wire diameter. In the case that your compression spring may have ground ends, you will only multiply the total coils by the wire diameter.

The proportional ratio between your spring’s wire diameter and mean diameter. It specifies the tightness of your compression spring’s coils.

Rate

The constant amount of force it takes your spring to travel one unit of measurement. (Load is proportional to displacement/deflection)

Loaded Height

The compressed length/height of your spring when a load has been placed on it.

Travel (Deflection)

The motion in which a spring is compressed. The distance traveled is the difference between the free length and the loaded height.

Load (Force)

The force being applied on the spring in order for it to travel.

Maximum Travel Considering Loaded Height

The maximum travel of your compression spring considering its solid height as to not exceed it.

Maximum Load Considering Loaded Height

The maximum load of your compression spring considering its solid height as to not exceed it.

True Maximum Travel

The travel you might be able to achieve out of your spring if you were to make the free length longer. To calculate how much you are able to increase the free length, subtract the “Max F” from the “True Max F”; the result will show you how much free length you’ll be able to add to the compression spring. If this value is equal to the maximum travel considering solid height, you will not be able to add any more travel.

True Maximum Load

The load you could be able to get out of your compression spring if you increased the free length. To calculate how much longer your free length can be, subtract the “Max F” from the “True Max F” and add anything less than or equal to the result to get more load out of your spring. If this value is equal to the maximum load considering solid height, you will not be able to add any more free length.

Endurance Limit

Maximum stress at which your compression spring will perform indefinitely without failure for a given minimum stress limit.

Slenderness Ratio/Buckling

The action of a compression spring bending to the side after being compressed due to having a long free length in proportion to its mean diameter.

Permanent Set

The product of exceeding the elastic properties of a compression spring thus keeping it from returning to its original free length once the load has been released.

The constant amount of force it takes your spring to travel one unit of measurement. (Load is proportional to displacement/deflection)

The compressed length/height of your spring when a load has been placed on it.

Travel (Deflection)

The motion in which a spring is compressed. The distance traveled is the difference between the free length and the loaded height.

Load (Force)

The force being applied on the spring in order for it to travel.

Maximum Travel Considering Loaded Height

The maximum travel of your compression spring considering its solid height as to not exceed it.

Maximum Load Considering Loaded Height

The maximum load of your compression spring considering its solid height as to not exceed it.

True Maximum Travel

The travel you might be able to achieve out of your spring if you were to make the free length longer. To calculate how much you are able to increase the free length, subtract the “Max F” from the “True Max F”; the result will show you how much free length you’ll be able to add to the compression spring. If this value is equal to the maximum travel considering solid height, you will not be able to add any more travel.

True Maximum Load

The load you could be able to get out of your compression spring if you increased the free length. To calculate how much longer your free length can be, subtract the “Max F” from the “True Max F” and add anything less than or equal to the result to get more load out of your spring. If this value is equal to the maximum load considering solid height, you will not be able to add any more free length.

Endurance Limit

Maximum stress at which your compression spring will perform indefinitely without failure for a given minimum stress limit.

Slenderness Ratio/Buckling

The action of a compression spring bending to the side after being compressed due to having a long free length in proportion to its mean diameter.

Permanent Set

The product of exceeding the elastic properties of a compression spring thus keeping it from returning to its original free length once the load has been released.

The motion in which a spring is compressed. The distance traveled is the difference between the free length and the loaded height.

The force being applied on the spring in order for it to travel.

Maximum Travel Considering Loaded Height

The maximum travel of your compression spring considering its solid height as to not exceed it.

Maximum Load Considering Loaded Height

The maximum load of your compression spring considering its solid height as to not exceed it.

True Maximum Travel

The travel you might be able to achieve out of your spring if you were to make the free length longer. To calculate how much you are able to increase the free length, subtract the “Max F” from the “True Max F”; the result will show you how much free length you’ll be able to add to the compression spring. If this value is equal to the maximum travel considering solid height, you will not be able to add any more travel.

True Maximum Load

The load you could be able to get out of your compression spring if you increased the free length. To calculate how much longer your free length can be, subtract the “Max F” from the “True Max F” and add anything less than or equal to the result to get more load out of your spring. If this value is equal to the maximum load considering solid height, you will not be able to add any more free length.

Endurance Limit

Maximum stress at which your compression spring will perform indefinitely without failure for a given minimum stress limit.

Slenderness Ratio/Buckling

The action of a compression spring bending to the side after being compressed due to having a long free length in proportion to its mean diameter.

Permanent Set

The product of exceeding the elastic properties of a compression spring thus keeping it from returning to its original free length once the load has been released.

The maximum travel of your compression spring considering its solid height as to not exceed it.

The maximum load of your compression spring considering its solid height as to not exceed it.

True Maximum Travel

The travel you might be able to achieve out of your spring if you were to make the free length longer. To calculate how much you are able to increase the free length, subtract the “Max F” from the “True Max F”; the result will show you how much free length you’ll be able to add to the compression spring. If this value is equal to the maximum travel considering solid height, you will not be able to add any more travel.

True Maximum Load

The load you could be able to get out of your compression spring if you increased the free length. To calculate how much longer your free length can be, subtract the “Max F” from the “True Max F” and add anything less than or equal to the result to get more load out of your spring. If this value is equal to the maximum load considering solid height, you will not be able to add any more free length.

Endurance Limit

Maximum stress at which your compression spring will perform indefinitely without failure for a given minimum stress limit.

Slenderness Ratio/Buckling

The action of a compression spring bending to the side after being compressed due to having a long free length in proportion to its mean diameter.

Permanent Set

The product of exceeding the elastic properties of a compression spring thus keeping it from returning to its original free length once the load has been released.

The travel you might be able to achieve out of your spring if you were to make the free length longer. To calculate how much you are able to increase the free length, subtract the “Max F” from the “True Max F”; the result will show you how much free length you’ll be able to add to the compression spring. If this value is equal to the maximum travel considering solid height, you will not be able to add any more travel.

The load you could be able to get out of your compression spring if you increased the free length. To calculate how much longer your free length can be, subtract the “Max F” from the “True Max F” and add anything less than or equal to the result to get more load out of your spring. If this value is equal to the maximum load considering solid height, you will not be able to add any more free length.

Endurance Limit

Maximum stress at which your compression spring will perform indefinitely without failure for a given minimum stress limit.

Slenderness Ratio/Buckling

The action of a compression spring bending to the side after being compressed due to having a long free length in proportion to its mean diameter.

Permanent Set

The product of exceeding the elastic properties of a compression spring thus keeping it from returning to its original free length once the load has been released.

Maximum stress at which your compression spring will perform indefinitely without failure for a given minimum stress limit.

The action of a compression spring bending to the side after being compressed due to having a long free length in proportion to its mean diameter.

Permanent Set

The product of exceeding the elastic properties of a compression spring thus keeping it from returning to its original free length once the load has been released.

The product of exceeding the elastic properties of a compression spring thus keeping it from returning to its original free length once the load has been released.

Compression Springs Physical Dimensions Nomenclature

Compression Springs End Types Nomenclature

English

English