Extension Springs Nomenclature

Definition: Extension springs are tightly coiled round wires keeping the coils compressed together in its free, unloaded state due to an amount of initial tension gathered between its coils.

Note: Click on the highlighted titles to learn more.

Tension Spring

Other term for extension springs.

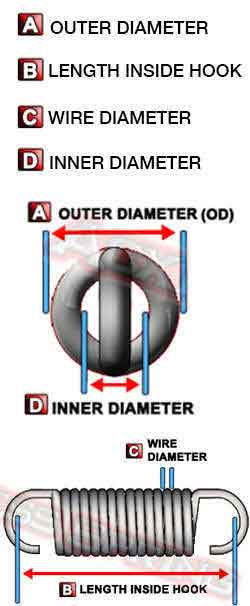

Wire Diameter

Measurement of wire thickness.

Outer Diameter

Measurement of the thickness of the coils that make up the extension spring’s body.

Inner Diameter

Measurement of the hole inside the spring’s coils formed by its helical shape.

Mean Diameter

The medium or intermediate diameter between the outer and inner diameter. Calculated by adding one wire diameter to the inner diameter or subtracting one wire diameter from the outer diameter.

Spring Index

The proportional ratio between a spring’s wire diameter and mean diameter. It describes the tightness of the spring’s coils.

Length Inside Hooks

Extension spring’s unloaded length measured from inside the hooks.

Body Length

The extension spring’s body is the section where you have the coils so the body length is the measurement of the body’s length. You may calculate the body length by adding the hook gaps together and subtracting them from the length inside hooks.

Hook Gap

The length of the gap between the spring’s body length and inner edge of the hook.

Active Coils

The active coils that make your tension spring function

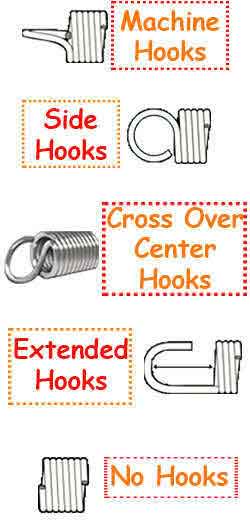

Machine Hooks

Most common type of hooks. They are made by bending 75% of the last coil.

Side Hooks

These hooks are made by completely bending the last coil to the side of the spring’s diameter.

Cross Over Center Hooks

The hooks are made from a side hook by making the hook cross the center of the spring’s diameter.

Extended Hooks

These hooks are longer than the hooks you are able to make off of the coils so these must be made directly from the machine to match the length requested by the user/customer.

No Hooks

A tension spring without hooks is used when another mating part will play the part of the hooks such as a bolt.

Rate (Constant)

The constant amount of force it will take the spring to travel one inch of distance in English measurements = Rate/inch or Newtons per millimeter = N/mm in metric.

Initial Tension

Additional force to the one already listed in rate. This force is energy already gathered in between the coils and is released when the tension spring is extended just enough so that you may see light in between the coils.

Extended Length

Length of spring when a load is applied.

Travel (Deflection)

The motion in which an extension spring is pulled or extended. The distance traveled is calculated by subtracting the length inside hooks from the extended length.

Load (Force):

The weight being applied on the spring’s hooks in order for it to reach an extended length.

Maximum Safe Travel Considering Hook Stress

The maximum amount of travel your spring is able to achieve considering the strength of its hooks.

Maximum Load Possible Considering Hook Stress:

The maximum amount of load your spring is able to undergo considering the strength of its hooks.

Maximum Safe Travel

The maximum safe travel you can achieve if your spring didn’t have hooks.

Maximum Load Possible

The maximum load possible your spring may undergo if it didn’t have hooks.

Endurance Limit

Maximum Stress at which your extension spring will perform indefinitely without failure for a given minimum stress limit.

Permanent Set

The product of exceeding the elastic properties of an extension spring thus keeping it from returning to its original unloaded length once the load has been released.

Other term for extension springs.

Measurement of wire thickness.

Outer Diameter

Measurement of the thickness of the coils that make up the extension spring’s body.

Inner Diameter

Measurement of the hole inside the spring’s coils formed by its helical shape.

Mean Diameter

The medium or intermediate diameter between the outer and inner diameter. Calculated by adding one wire diameter to the inner diameter or subtracting one wire diameter from the outer diameter.

Spring Index

The proportional ratio between a spring’s wire diameter and mean diameter. It describes the tightness of the spring’s coils.

Length Inside Hooks

Extension spring’s unloaded length measured from inside the hooks.

Body Length

The extension spring’s body is the section where you have the coils so the body length is the measurement of the body’s length. You may calculate the body length by adding the hook gaps together and subtracting them from the length inside hooks.

Hook Gap

The length of the gap between the spring’s body length and inner edge of the hook.

Active Coils

The active coils that make your tension spring function

Machine Hooks

Most common type of hooks. They are made by bending 75% of the last coil.

Side Hooks

These hooks are made by completely bending the last coil to the side of the spring’s diameter.

Cross Over Center Hooks

The hooks are made from a side hook by making the hook cross the center of the spring’s diameter.

Extended Hooks

These hooks are longer than the hooks you are able to make off of the coils so these must be made directly from the machine to match the length requested by the user/customer.

No Hooks

A tension spring without hooks is used when another mating part will play the part of the hooks such as a bolt.

Rate (Constant)

The constant amount of force it will take the spring to travel one inch of distance in English measurements = Rate/inch or Newtons per millimeter = N/mm in metric.

Initial Tension

Additional force to the one already listed in rate. This force is energy already gathered in between the coils and is released when the tension spring is extended just enough so that you may see light in between the coils.

Extended Length

Length of spring when a load is applied.

Travel (Deflection)

The motion in which an extension spring is pulled or extended. The distance traveled is calculated by subtracting the length inside hooks from the extended length.

Load (Force):

The weight being applied on the spring’s hooks in order for it to reach an extended length.

Maximum Safe Travel Considering Hook Stress

The maximum amount of travel your spring is able to achieve considering the strength of its hooks.

Maximum Load Possible Considering Hook Stress:

The maximum amount of load your spring is able to undergo considering the strength of its hooks.

Maximum Safe Travel

The maximum safe travel you can achieve if your spring didn’t have hooks.

Maximum Load Possible

The maximum load possible your spring may undergo if it didn’t have hooks.

Endurance Limit

Maximum Stress at which your extension spring will perform indefinitely without failure for a given minimum stress limit.

Permanent Set

The product of exceeding the elastic properties of an extension spring thus keeping it from returning to its original unloaded length once the load has been released.

Measurement of the thickness of the coils that make up the extension spring’s body.

Measurement of the hole inside the spring’s coils formed by its helical shape.

Mean Diameter

The medium or intermediate diameter between the outer and inner diameter. Calculated by adding one wire diameter to the inner diameter or subtracting one wire diameter from the outer diameter.

Spring Index

The proportional ratio between a spring’s wire diameter and mean diameter. It describes the tightness of the spring’s coils.

Length Inside Hooks

Extension spring’s unloaded length measured from inside the hooks.

Body Length

The extension spring’s body is the section where you have the coils so the body length is the measurement of the body’s length. You may calculate the body length by adding the hook gaps together and subtracting them from the length inside hooks.

Hook Gap

The length of the gap between the spring’s body length and inner edge of the hook.

Active Coils

The active coils that make your tension spring function

Machine Hooks

Most common type of hooks. They are made by bending 75% of the last coil.

Side Hooks

These hooks are made by completely bending the last coil to the side of the spring’s diameter.

Cross Over Center Hooks

The hooks are made from a side hook by making the hook cross the center of the spring’s diameter.

Extended Hooks

These hooks are longer than the hooks you are able to make off of the coils so these must be made directly from the machine to match the length requested by the user/customer.

No Hooks

A tension spring without hooks is used when another mating part will play the part of the hooks such as a bolt.

Rate (Constant)

The constant amount of force it will take the spring to travel one inch of distance in English measurements = Rate/inch or Newtons per millimeter = N/mm in metric.

Initial Tension

Additional force to the one already listed in rate. This force is energy already gathered in between the coils and is released when the tension spring is extended just enough so that you may see light in between the coils.

Extended Length

Length of spring when a load is applied.

Travel (Deflection)

The motion in which an extension spring is pulled or extended. The distance traveled is calculated by subtracting the length inside hooks from the extended length.

Load (Force):

The weight being applied on the spring’s hooks in order for it to reach an extended length.

Maximum Safe Travel Considering Hook Stress

The maximum amount of travel your spring is able to achieve considering the strength of its hooks.

Maximum Load Possible Considering Hook Stress:

The maximum amount of load your spring is able to undergo considering the strength of its hooks.

Maximum Safe Travel

The maximum safe travel you can achieve if your spring didn’t have hooks.

Maximum Load Possible

The maximum load possible your spring may undergo if it didn’t have hooks.

Endurance Limit

Maximum Stress at which your extension spring will perform indefinitely without failure for a given minimum stress limit.

Permanent Set

The product of exceeding the elastic properties of an extension spring thus keeping it from returning to its original unloaded length once the load has been released.

The medium or intermediate diameter between the outer and inner diameter. Calculated by adding one wire diameter to the inner diameter or subtracting one wire diameter from the outer diameter.

The proportional ratio between a spring’s wire diameter and mean diameter. It describes the tightness of the spring’s coils.

Length Inside Hooks

Extension spring’s unloaded length measured from inside the hooks.

Body Length

The extension spring’s body is the section where you have the coils so the body length is the measurement of the body’s length. You may calculate the body length by adding the hook gaps together and subtracting them from the length inside hooks.

Hook Gap

The length of the gap between the spring’s body length and inner edge of the hook.

Active Coils

The active coils that make your tension spring function

Machine Hooks

Most common type of hooks. They are made by bending 75% of the last coil.

Side Hooks

These hooks are made by completely bending the last coil to the side of the spring’s diameter.

Cross Over Center Hooks

The hooks are made from a side hook by making the hook cross the center of the spring’s diameter.

Extended Hooks

These hooks are longer than the hooks you are able to make off of the coils so these must be made directly from the machine to match the length requested by the user/customer.

No Hooks

A tension spring without hooks is used when another mating part will play the part of the hooks such as a bolt.

Rate (Constant)

The constant amount of force it will take the spring to travel one inch of distance in English measurements = Rate/inch or Newtons per millimeter = N/mm in metric.

Initial Tension

Additional force to the one already listed in rate. This force is energy already gathered in between the coils and is released when the tension spring is extended just enough so that you may see light in between the coils.

Extended Length

Length of spring when a load is applied.

Travel (Deflection)

The motion in which an extension spring is pulled or extended. The distance traveled is calculated by subtracting the length inside hooks from the extended length.

Load (Force):

The weight being applied on the spring’s hooks in order for it to reach an extended length.

Maximum Safe Travel Considering Hook Stress

The maximum amount of travel your spring is able to achieve considering the strength of its hooks.

Maximum Load Possible Considering Hook Stress:

The maximum amount of load your spring is able to undergo considering the strength of its hooks.

Maximum Safe Travel

The maximum safe travel you can achieve if your spring didn’t have hooks.

Maximum Load Possible

The maximum load possible your spring may undergo if it didn’t have hooks.

Endurance Limit

Maximum Stress at which your extension spring will perform indefinitely without failure for a given minimum stress limit.

Permanent Set

The product of exceeding the elastic properties of an extension spring thus keeping it from returning to its original unloaded length once the load has been released.

Extension spring’s unloaded length measured from inside the hooks.

The extension spring’s body is the section where you have the coils so the body length is the measurement of the body’s length. You may calculate the body length by adding the hook gaps together and subtracting them from the length inside hooks.

Hook Gap

The length of the gap between the spring’s body length and inner edge of the hook.

Active Coils

The active coils that make your tension spring function

Machine Hooks

Most common type of hooks. They are made by bending 75% of the last coil.

Side Hooks

These hooks are made by completely bending the last coil to the side of the spring’s diameter.

Cross Over Center Hooks

The hooks are made from a side hook by making the hook cross the center of the spring’s diameter.

Extended Hooks

These hooks are longer than the hooks you are able to make off of the coils so these must be made directly from the machine to match the length requested by the user/customer.

No Hooks

A tension spring without hooks is used when another mating part will play the part of the hooks such as a bolt.

Rate (Constant)

The constant amount of force it will take the spring to travel one inch of distance in English measurements = Rate/inch or Newtons per millimeter = N/mm in metric.

Initial Tension

Additional force to the one already listed in rate. This force is energy already gathered in between the coils and is released when the tension spring is extended just enough so that you may see light in between the coils.

Extended Length

Length of spring when a load is applied.

Travel (Deflection)

The motion in which an extension spring is pulled or extended. The distance traveled is calculated by subtracting the length inside hooks from the extended length.

Load (Force):

The weight being applied on the spring’s hooks in order for it to reach an extended length.

Maximum Safe Travel Considering Hook Stress

The maximum amount of travel your spring is able to achieve considering the strength of its hooks.

Maximum Load Possible Considering Hook Stress:

The maximum amount of load your spring is able to undergo considering the strength of its hooks.

Maximum Safe Travel

The maximum safe travel you can achieve if your spring didn’t have hooks.

Maximum Load Possible

The maximum load possible your spring may undergo if it didn’t have hooks.

Endurance Limit

Maximum Stress at which your extension spring will perform indefinitely without failure for a given minimum stress limit.

Permanent Set

The product of exceeding the elastic properties of an extension spring thus keeping it from returning to its original unloaded length once the load has been released.

The length of the gap between the spring’s body length and inner edge of the hook.

The active coils that make your tension spring function

Machine Hooks

Most common type of hooks. They are made by bending 75% of the last coil.

Side Hooks

These hooks are made by completely bending the last coil to the side of the spring’s diameter.

Cross Over Center Hooks

The hooks are made from a side hook by making the hook cross the center of the spring’s diameter.

Extended Hooks

These hooks are longer than the hooks you are able to make off of the coils so these must be made directly from the machine to match the length requested by the user/customer.

No Hooks

A tension spring without hooks is used when another mating part will play the part of the hooks such as a bolt.

Rate (Constant)

The constant amount of force it will take the spring to travel one inch of distance in English measurements = Rate/inch or Newtons per millimeter = N/mm in metric.

Initial Tension

Additional force to the one already listed in rate. This force is energy already gathered in between the coils and is released when the tension spring is extended just enough so that you may see light in between the coils.

Extended Length

Length of spring when a load is applied.

Travel (Deflection)

The motion in which an extension spring is pulled or extended. The distance traveled is calculated by subtracting the length inside hooks from the extended length.

Load (Force):

The weight being applied on the spring’s hooks in order for it to reach an extended length.

Maximum Safe Travel Considering Hook Stress

The maximum amount of travel your spring is able to achieve considering the strength of its hooks.

Maximum Load Possible Considering Hook Stress:

The maximum amount of load your spring is able to undergo considering the strength of its hooks.

Maximum Safe Travel

The maximum safe travel you can achieve if your spring didn’t have hooks.

Maximum Load Possible

The maximum load possible your spring may undergo if it didn’t have hooks.

Endurance Limit

Maximum Stress at which your extension spring will perform indefinitely without failure for a given minimum stress limit.

Permanent Set

The product of exceeding the elastic properties of an extension spring thus keeping it from returning to its original unloaded length once the load has been released.

Most common type of hooks. They are made by bending 75% of the last coil.

These hooks are made by completely bending the last coil to the side of the spring’s diameter.

Cross Over Center Hooks

The hooks are made from a side hook by making the hook cross the center of the spring’s diameter.

Extended Hooks

These hooks are longer than the hooks you are able to make off of the coils so these must be made directly from the machine to match the length requested by the user/customer.

No Hooks

A tension spring without hooks is used when another mating part will play the part of the hooks such as a bolt.

Rate (Constant)

The constant amount of force it will take the spring to travel one inch of distance in English measurements = Rate/inch or Newtons per millimeter = N/mm in metric.

Initial Tension

Additional force to the one already listed in rate. This force is energy already gathered in between the coils and is released when the tension spring is extended just enough so that you may see light in between the coils.

Extended Length

Length of spring when a load is applied.

Travel (Deflection)

The motion in which an extension spring is pulled or extended. The distance traveled is calculated by subtracting the length inside hooks from the extended length.

Load (Force):

The weight being applied on the spring’s hooks in order for it to reach an extended length.

Maximum Safe Travel Considering Hook Stress

The maximum amount of travel your spring is able to achieve considering the strength of its hooks.

Maximum Load Possible Considering Hook Stress:

The maximum amount of load your spring is able to undergo considering the strength of its hooks.

Maximum Safe Travel

The maximum safe travel you can achieve if your spring didn’t have hooks.

Maximum Load Possible

The maximum load possible your spring may undergo if it didn’t have hooks.

Endurance Limit

Maximum Stress at which your extension spring will perform indefinitely without failure for a given minimum stress limit.

Permanent Set

The product of exceeding the elastic properties of an extension spring thus keeping it from returning to its original unloaded length once the load has been released.

The hooks are made from a side hook by making the hook cross the center of the spring’s diameter.

These hooks are longer than the hooks you are able to make off of the coils so these must be made directly from the machine to match the length requested by the user/customer.

No Hooks

A tension spring without hooks is used when another mating part will play the part of the hooks such as a bolt.

Rate (Constant)

The constant amount of force it will take the spring to travel one inch of distance in English measurements = Rate/inch or Newtons per millimeter = N/mm in metric.

Initial Tension

Additional force to the one already listed in rate. This force is energy already gathered in between the coils and is released when the tension spring is extended just enough so that you may see light in between the coils.

Extended Length

Length of spring when a load is applied.

Travel (Deflection)

The motion in which an extension spring is pulled or extended. The distance traveled is calculated by subtracting the length inside hooks from the extended length.

Load (Force):

The weight being applied on the spring’s hooks in order for it to reach an extended length.

Maximum Safe Travel Considering Hook Stress

The maximum amount of travel your spring is able to achieve considering the strength of its hooks.

Maximum Load Possible Considering Hook Stress:

The maximum amount of load your spring is able to undergo considering the strength of its hooks.

Maximum Safe Travel

The maximum safe travel you can achieve if your spring didn’t have hooks.

Maximum Load Possible

The maximum load possible your spring may undergo if it didn’t have hooks.

Endurance Limit

Maximum Stress at which your extension spring will perform indefinitely without failure for a given minimum stress limit.

Permanent Set

The product of exceeding the elastic properties of an extension spring thus keeping it from returning to its original unloaded length once the load has been released.

A tension spring without hooks is used when another mating part will play the part of the hooks such as a bolt.

The constant amount of force it will take the spring to travel one inch of distance in English measurements = Rate/inch or Newtons per millimeter = N/mm in metric.

Initial Tension

Additional force to the one already listed in rate. This force is energy already gathered in between the coils and is released when the tension spring is extended just enough so that you may see light in between the coils.

Extended Length

Length of spring when a load is applied.

Travel (Deflection)

The motion in which an extension spring is pulled or extended. The distance traveled is calculated by subtracting the length inside hooks from the extended length.

Load (Force):

The weight being applied on the spring’s hooks in order for it to reach an extended length.

Maximum Safe Travel Considering Hook Stress

The maximum amount of travel your spring is able to achieve considering the strength of its hooks.

Maximum Load Possible Considering Hook Stress:

The maximum amount of load your spring is able to undergo considering the strength of its hooks.

Maximum Safe Travel

The maximum safe travel you can achieve if your spring didn’t have hooks.

Maximum Load Possible

The maximum load possible your spring may undergo if it didn’t have hooks.

Endurance Limit

Maximum Stress at which your extension spring will perform indefinitely without failure for a given minimum stress limit.

Permanent Set

The product of exceeding the elastic properties of an extension spring thus keeping it from returning to its original unloaded length once the load has been released.

Additional force to the one already listed in rate. This force is energy already gathered in between the coils and is released when the tension spring is extended just enough so that you may see light in between the coils.

Length of spring when a load is applied.

Travel (Deflection)

The motion in which an extension spring is pulled or extended. The distance traveled is calculated by subtracting the length inside hooks from the extended length.

Load (Force):

The weight being applied on the spring’s hooks in order for it to reach an extended length.

Maximum Safe Travel Considering Hook Stress

The maximum amount of travel your spring is able to achieve considering the strength of its hooks.

Maximum Load Possible Considering Hook Stress:

The maximum amount of load your spring is able to undergo considering the strength of its hooks.

Maximum Safe Travel

The maximum safe travel you can achieve if your spring didn’t have hooks.

Maximum Load Possible

The maximum load possible your spring may undergo if it didn’t have hooks.

Endurance Limit

Maximum Stress at which your extension spring will perform indefinitely without failure for a given minimum stress limit.

Permanent Set

The product of exceeding the elastic properties of an extension spring thus keeping it from returning to its original unloaded length once the load has been released.

The motion in which an extension spring is pulled or extended. The distance traveled is calculated by subtracting the length inside hooks from the extended length.

The weight being applied on the spring’s hooks in order for it to reach an extended length.

Maximum Safe Travel Considering Hook Stress

The maximum amount of travel your spring is able to achieve considering the strength of its hooks.

Maximum Load Possible Considering Hook Stress:

The maximum amount of load your spring is able to undergo considering the strength of its hooks.

Maximum Safe Travel

The maximum safe travel you can achieve if your spring didn’t have hooks.

Maximum Load Possible

The maximum load possible your spring may undergo if it didn’t have hooks.

Endurance Limit

Maximum Stress at which your extension spring will perform indefinitely without failure for a given minimum stress limit.

Permanent Set

The product of exceeding the elastic properties of an extension spring thus keeping it from returning to its original unloaded length once the load has been released.

The maximum amount of travel your spring is able to achieve considering the strength of its hooks.

The maximum amount of load your spring is able to undergo considering the strength of its hooks.

Maximum Safe Travel

The maximum safe travel you can achieve if your spring didn’t have hooks.

Maximum Load Possible

The maximum load possible your spring may undergo if it didn’t have hooks.

Endurance Limit

Maximum Stress at which your extension spring will perform indefinitely without failure for a given minimum stress limit.

Permanent Set

The product of exceeding the elastic properties of an extension spring thus keeping it from returning to its original unloaded length once the load has been released.

The maximum safe travel you can achieve if your spring didn’t have hooks.

The maximum load possible your spring may undergo if it didn’t have hooks.

Endurance Limit

Maximum Stress at which your extension spring will perform indefinitely without failure for a given minimum stress limit.

Permanent Set

The product of exceeding the elastic properties of an extension spring thus keeping it from returning to its original unloaded length once the load has been released.

Maximum Stress at which your extension spring will perform indefinitely without failure for a given minimum stress limit.

The product of exceeding the elastic properties of an extension spring thus keeping it from returning to its original unloaded length once the load has been released.

Extension Springs Physical Dimensions Nomenclature

Extension Springs Hook Types Nomenclature

English

English