Standard Spring Dimension Tolerances in Metric

At China Spring Products Corp we aim to manufacture your custom springs with precision as there are certain standard industry tolerances that must be adhered to. Below you will find a list of all the standard tolerances for compression springs, extension springs, torsion springs, garter springs, and conical and barrel springs.

Standard Compression Spring Tolerances

Outer/Inner Diameter Tolerances

- 0.6350mm to 1.2700mm ± 0.0508mm

- 1.2701mm to 2.5400mm ± 0.0762mm

- 2.5401mm to 6.3500mm ± 0.1270mm

- 6.3501mm to 12.700mm ± 0.2032mm

- 12.701mm to 21.590mm ± 0.3810mm

- 21.591mm to 28.575mm ± 0.5080mm

- 28.576mm to 31.750mm ± 0.6350mm

- 31.751mm to 37.592mm ± 0.7620mm

- 37.593mm to 44.450mm ± 1.0160mm

- 44.451mm to 50.800mm ± 1.3970mm

- 50.801mm to 57.150mm ± 1.6510mm

- 57.151mm to 63.500mm ± 1.9050mm

- 63.501mm to 69.850mm ± 2.2860mm

- 69.851mm to 76.200mm ± 2.9210mm

- 76.201mm to 88.900mm ± 3.3020mm

- 88.901mm to 101.60mm ± 4.0640mm

- 101.61mm to 114.30mm ± 4.8260mm

- 114.31mm to 127.00mm ± 5.7150mm

- 127.01mm to 139.70mm ± 6.3500mm

- 139.71mm to 152.40mm ± 7.1120mm

- 152.41mm to 165.10mm ± 7.8740mm

- 165.11mm to 177.80mm ± 8.8900mm

- 177.81mm to 190.50mm ± 9.7790mm

- 190.51mm to 203.20mm ± 10.541mm

- 203.21mm to 215.90mm ± 11.557mm

- 215.91mm to 228.60mm ± 12.446mm

- 228.61mm to 241.30mm ± 13.335mm

- 241.31mm to 254.00mm ± 14.351mm

Wire Diameter Tolerances

Note: China Spring Products Corp does not manufacture the wire used to manufacture springs.

The following tolerances apply for the following wire types:

- Hard Drawn HD A679

- Hard Drawn ASTM A227

- Music Wire ASTM A228

- Oil Tempered MB A229

- Carbon Valve A230

- Phosphor Bronze Grade A B159

- Beryllium Copper B197

- Stainless Steel 17-7 ASTM A313

- Stainless Steel 302 ASTM A313

- Stainless Steel 316 ASTM A316

- 0.1270mm to 0.4572mm ± 0.01270mm

- 0.4573mm to 1.0160mm ± 0.01524mm

- 1.0161mm to 1.5875mm ± 0.01778mm

- 1.5876mm to 2.2860mm ± 0.02032mm

- 2.2861mm to 3.1750mm ± 0.02286mm

- 3.1751mm to 6.3500mm ± 0.02540mm

- 6.3501mm to 9.5250mm ± 0.03175mm

- 9.5251mm to 12.700mm ± 0.03493mm

- 12.701mm to 15.875mm ± 0.03810mm

The following tolerances apply for the following wire types:

- Chrome Silicon A401

- 5160 H

- 2.5400mm to 3.1750mm ± 0.02286mm

- 3.1751mm to 6.3500mm ± 0.02540mm

- 6.3501mm to 9.5250mm ± 0.03175mm

- 9.5251mm to 12.700mm ± 0.03493mm

- 12.701mm to 15.875mm ± 0.03810mm

- 15.876mm to 19.050mm ± 0.04064mm

- 19.051mm to 31.750mm ± 0.04318mm

Free Length Tolerances

- 0.0254mm to 12.700mm ± 0.381mm

- 12.701mm to 25.400mm ± 0.508mm

- 25.401mm to 50.800mm ± 1.270mm

- 50.801mm to 101.60mm ± 2.540mm

- 101.61mm to 203.20mm ± 5.080mm

- 203.21mm to 254.00mm ± 7.620mm

- 254.01mm to 381.00mm ± 10.160mm

- 381.01mm to 508.00mm ± 12.700mm

- 508.01mm to 635.00mm ± 16.510mm

- 635.01mm to 762.00mm ± 20.320mm

- 762.01mm to 889.00mm ± 25.400mm

- 889.01mm to 1016.0mm ± 30.480mm

- 1016.1mm to 1219.2mm ± 34.925mm

- 1219.3mm and up ± 38.100mm

Total Coils Tolerances

±¼ coil or reference if load or rate needs to be met.

Solid Height Tolerances

±7% or reference if load or rate needs to be met.

Rate Tolerances

Spring rate has a manufacturing tolerance of ±10%

Working Loads Tolerance

Working loads has a manufacturing tolerance of ±10%

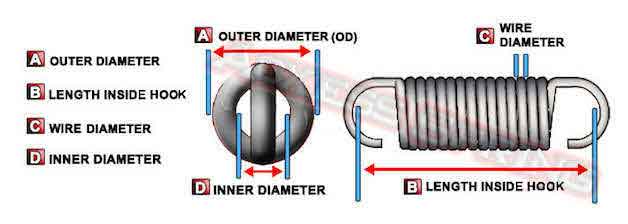

Outer/Inner Diameter Tolerances

- 0.6350mm to 1.2700mm ± 0.0508mm

- 1.2701mm to 2.5400mm ± 0.0762mm

- 2.5401mm to 6.3500mm ± 0.1270mm

- 6.3501mm to 12.700mm ± 0.2032mm

- 12.701mm to 21.590mm ± 0.3810mm

- 21.591mm to 28.575mm ± 0.5080mm

- 28.576mm to 31.750mm ± 0.6350mm

- 31.751mm to 37.592mm ± 0.7620mm

- 37.593mm to 44.450mm ± 1.0160mm

- 44.451mm to 50.800mm ± 1.3970mm

- 50.801mm to 57.150mm ± 1.6510mm

- 57.151mm to 63.500mm ± 1.9050mm

- 63.501mm to 69.850mm ± 2.2860mm

- 69.851mm to 76.200mm ± 2.9210mm

- 76.201mm to 88.900mm ± 3.3020mm

- 88.901mm to 101.60mm ± 4.0640mm

- 101.61mm to 114.30mm ± 4.8260mm

- 114.31mm to 127.00mm ± 5.7150mm

- 127.01mm to 139.70mm ± 6.3500mm

- 139.71mm to 152.40mm ± 7.1120mm

- 152.41mm to 165.10mm ± 7.8740mm

- 165.11mm to 177.80mm ± 8.8900mm

Wire Diameter Tolerances

Note: China Spring Products Corp does not manufacture the wire used to manufacture springs.

The following tolerances apply for the following wire types:

- Hard Drawn HD A679

- Hard Drawn ASTM A227

- Music Wire ASTM A228

- Oil Tempered MB A229

- Carbon Valve A230

- Phosphor Bronze Grade A B159

- Beryllium Copper B197

- Stainless Steel 17-7 ASTM A313

- Stainless Steel 302 ASTM A313

- Stainless Steel 316 ASTM A316

- 0.1270mm to 0.4572mm ± 0.01270mm

- 0.4573mm to 1.0160mm ± 0.01524mm

- 1.0161mm to 1.5875mm ± 0.01778mm

- 1.5876mm to 2.2860mm ± 0.02032mm

- 2.2861mm to 3.1750mm ± 0.02286mm

- 3.1751mm to 6.3500mm ± 0.02540mm

- 6.3501mm to 9.5250mm ± 0.03175mm

- 9.5251mm to 12.700mm ± 0.03493mm

- 12.701mm to 15.875mm ± 0.03810mm

The following tolerances apply for the following wire types:

- Chrome Silicon A401

- 5160 H

- 2.5400mm to 3.1750mm ± 0.02286mm

- 3.1751mm to 6.3500mm ± 0.02540mm

- 6.3501mm to 9.5250mm ± 0.03175mm

- 9.5251mm to 12.700mm ± 0.03493mm

- 12.701mm to 15.875mm ± 0.03810mm

- 15.876mm to 19.050mm ± 0.04064mm

- 19.051mm to 31.750mm ± 0.04318mm

Length Inside Hooks Tolerances

- 0.0254mm to 12.700mm ± 0.381mm

- 12.701mm to 25.400mm ± 0.508mm

- 25.401mm to 50.800mm ± 0.762mm

- 50.801mm to 101.60mm ± 1.270mm

- 101.61mm to 203.20mm ± 2.362mm

- 203.21mm to 254.00mm ± 3.962mm

- 254.01mm to 381.00mm ± 6.250mm

- 381.01mm to 508.00mm ± 8.890mm

- 508.01mm to 635.00mm ± 12.70mm

- 635.01mm to 762.00mm ± 16.51mm

- 762.01mm to 889.00mm ± 20.32mm

- 889.01mm to 1016.0mm ± 25.40mm

- 1016.1mm to 1219.2mm ± 31.75mm

Rate Tolerances

Spring rate has a manufacturing tolerance of ±10%

Working Loads Tolerance

Working loads has a manufacturing tolerance of ±10%

Initial Tension Tolerances

Reference Only

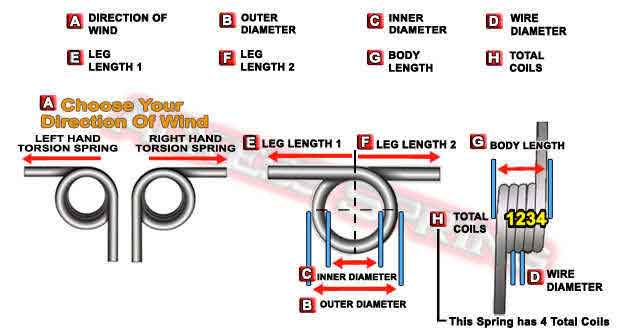

Outer/Inner Diameter Tolerances

- 0.6350mm to 1.2700mm ± 0.0508mm

- 1.2701mm to 2.5400mm ± 0.0762mm

- 2.5401mm to 6.3500mm ± 0.1270mm

- 6.3501mm to 12.700mm ± 0.2032mm

- 12.701mm to 21.590mm ± 0.3810mm

- 21.591mm to 28.575mm ± 0.5080mm

- 28.576mm to 31.750mm ± 0.6350mm

- 31.751mm to 37.592mm ± 0.7620mm

- 37.593mm to 44.450mm ± 1.0160mm

- 44.451mm to 50.800mm ± 1.3970mm

- 50.801mm to 57.150mm ± 1.6510mm

- 57.151mm to 63.500mm ± 1.9050mm

- 63.501mm to 69.850mm ± 2.2860mm

- 69.851mm to 76.200mm ± 2.9210mm

- 76.201mm to 88.900mm ± 3.3020mm

- 88.901mm to 101.60mm ± 4.0640mm

- 101.61mm to 114.30mm ± 4.8260mm

- 114.31mm to 127.00mm ± 5.7150mm

- 127.01mm to 139.70mm ± 6.3500mm

- 139.71mm to 152.40mm ± 7.1120mm

- 152.41mm to 165.10mm ± 7.8740mm

- 165.11mm to 177.80mm ± 8.8900mm

- 177.81mm to 190.50mm ± 9.7790mm

- 190.51mm to 203.20mm ± 10.541mm

- 203.21mm to 215.90mm ± 11.557mm

- 215.91mm to 228.60mm ± 12.446mm

- 228.61mm to 241.30mm ± 13.335mm

- 241.31mm to 254.00mm ± 14.351mm

Wire Diameter Tolerances

Note: China Spring Products Corp does not manufacture the wire used to manufacture springs.

The following tolerances apply for the following wire types:

- Hard Drawn HD A679

- Hard Drawn ASTM A227

- Music Wire ASTM A228

- Oil Tempered MB A229

- Carbon Valve A230

- Phosphor Bronze Grade A B159

- Beryllium Copper B197

- Stainless Steel 17-7 ASTM A313

- Stainless Steel 302 ASTM A313

- Stainless Steel 316 ASTM A316

- 0.1270mm to 0.4572mm ± 0.01270mm

- 0.4573mm to 1.0160mm ± 0.01524mm

- 1.0161mm to 1.5875mm ± 0.01778mm

- 1.5876mm to 2.2860mm ± 0.02032mm

- 2.2861mm to 3.1750mm ± 0.02286mm

- 3.1751mm to 6.3500mm ± 0.02540mm

- 6.3501mm to 9.5250mm ± 0.03175mm

- 9.5251mm to 12.700mm ± 0.03493mm

- 12.701mm to 15.875mm ± 0.03810mm

The following tolerances apply for the following wire types:

- Chrome Silicon A401

- 5160 H

- 2.5400mm to 3.1750mm ± 0.02286mm

- 3.1751mm to 6.3500mm ± 0.02540mm

- 6.3501mm to 9.5250mm ± 0.03175mm

- 9.5251mm to 12.700mm ± 0.03493mm

- 12.701mm to 15.875mm ± 0.03810mm

- 15.876mm to 19.050mm ± 0.04064mm

- 19.051mm to 31.750mm ± 0.04318mm

Leg Length Tolerances

- 0.508mm to 1.270mm ± 0.254mm

- 1.271mm to 6.350mm ± 0.635mm

- 6.351mm to 25.40mm ± 0.889mm

- 25.41mm to 50.80mm ± 1.270mm

- 50.81mm to 101.6mm ± 2.032mm

- 101.7mm to 190.5mm ± 3.810mm

- 190.6mm to 254.0mm ± 6.985mm

Total Coils/Free Position Tolerances

±3/16 coil or reference if torque or rate needs to be met.

Rate Tolerances

Spring rate has a manufacturing tolerance of ±10%

Torque Tolerance

Torque has a manufacturing tolerance of ±10%

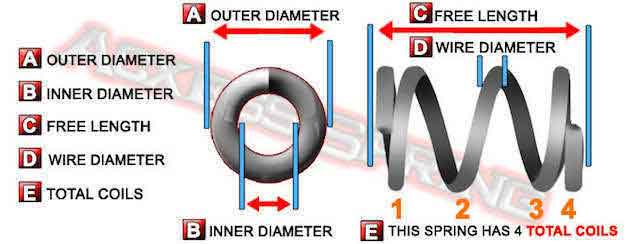

Standard Conical and Barrel Spring Tolerances

Small & Large Outer/Inner Diameter

- 0.6350mm to 1.2700mm ± 0.0508mm

- 1.2701mm to 2.5400mm ± 0.0762mm

- 2.5401mm to 6.3500mm ± 0.1270mm

- 6.3501mm to 12.700mm ± 0.2032mm

- 12.701mm to 21.590mm ± 0.3810mm

- 21.591mm to 28.575mm ± 0.5080mm

- 28.576mm to 31.750mm ± 0.6350mm

- 31.751mm to 37.592mm ± 0.7620mm

- 37.593mm to 44.450mm ± 1.0160mm

- 44.451mm to 50.800mm ± 1.3970mm

- 50.801mm to 57.150mm ± 1.6510mm

- 57.151mm to 63.500mm ± 1.9050mm

- 63.501mm to 69.850mm ± 2.2860mm

- 69.851mm to 76.200mm ± 2.9210mm

- 76.201mm to 88.900mm ± 3.3020mm

- 88.901mm to 101.60mm ± 4.0640mm

- 101.61mm to 114.30mm ± 4.8260mm

Wire Diameter Tolerances

Note: China Spring Products Corp does not manufacture the wire used to manufacture springs.

The following tolerances apply for the following wire types:

- Hard Drawn HD A679

- Hard Drawn ASTM A227

- Music Wire ASTM A228

- Oil Tempered MB A229

- Carbon Valve A230

- Phosphor Bronze Grade A B159

- Beryllium Copper B197

- Stainless Steel 17-7 ASTM A313

- Stainless Steel 302 ASTM A313

- Stainless Steel 316 ASTM A316

- 0.1270mm to 0.4572mm ± 0.01270mm

- 0.4573mm to 1.0160mm ± 0.01524mm

- 1.0161mm to 1.5875mm ± 0.01778mm

- 1.5876mm to 2.2860mm ± 0.02032mm

- 2.2861mm to 3.1750mm ± 0.02286mm

- 3.1751mm to 6.3500mm ± 0.02540mm

- 6.3501mm to 9.5250mm ± 0.03175mm

- 9.5251mm to 12.700mm ± 0.03493mm

- 12.701mm to 15.875mm ± 0.03810mm

The following tolerances apply for the following wire types:

- Chrome Silicon A401

- 5160 H

- 2.5400mm to 3.1750mm ± 0.02286mm

- 3.1751mm to 6.3500mm ± 0.02540mm

- 6.3501mm to 9.5250mm ± 0.03175mm

- 9.5251mm to 12.700mm ± 0.03493mm

- 12.701mm to 15.875mm ± 0.03810mm

- 15.876mm to 19.050mm ± 0.04064mm

- 19.051mm to 31.750mm ± 0.04318mm

Free Length Tolerances

- 0.0254mm to 12.700mm ± 0.381mm

- 12.701mm to 25.400mm ± 0.508mm

- 25.401mm to 50.800mm ± 0.762mm

- 50.801mm to 101.60mm ± 1.270mm

- 101.61mm to 203.20mm ± 2.362mm

- 203.21mm to 254.00mm ± 3.962mm

- 254.01mm to 381.00mm ± 6.250mm

- 381.01mm to 508.00mm ± 8.890mm

- 508.01mm to 635.00mm ± 12.70mm

- 635.01mm to 762.00mm ± 16.51mm

- 762.01mm to 889.00mm ± 20.32mm

- 889.01mm to 1016.0mm ± 25.40mm

- 1016.1mm to 1219.2mm ± 31.75mm

Total Coils Tolerances

±¼ coil or reference if load or rate needs to be met.

Rate Tolerance

Spring rate has a manufacturing tolerance of ±10%

Working Loads Tolerance

Working loads has a manufacturing tolerance of ±10%

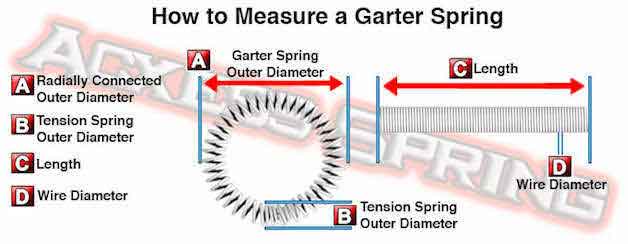

Outer/Inner Diameter Tolerances

- 0.6350mm to 1.2700mm ± 0.0508mm

- 1.2701mm to 2.5400mm ± 0.0762mm

- 2.5401mm to 6.3500mm ± 0.1270mm

- 6.3501mm to 12.700mm ± 0.2032mm

- 12.701mm to 21.590mm ± 0.3810mm

- 21.591mm to 28.575mm ± 0.5080mm

- 28.576mm to 31.750mm ± 0.6350mm

- 31.751mm to 37.592mm ± 0.7620mm

- 37.593mm to 44.450mm ± 1.0160mm

- 44.451mm to 50.800mm ± 1.3970mm

- 50.801mm to 57.150mm ± 1.6510mm

- 57.151mm to 63.500mm ± 1.9050mm

- 63.501mm to 69.850mm ± 2.2860mm

- 69.851mm to 76.200mm ± 2.9210mm

- 76.201mm to 88.900mm ± 3.3020mm

- 88.901mm to 101.60mm ± 4.0640mm

- 101.61mm to 114.30mm ± 4.8260mm

- 114.31mm to 127.00mm ± 5.7150mm

- 127.01mm to 139.70mm ± 6.3500mm

- 139.71mm to 152.40mm ± 7.1120mm

- 152.41mm to 165.10mm ± 7.8740mm

- 165.11mm to 177.80mm ± 8.8900mm

Working Loads Tolerance

Working loads has a manufacturing tolerance of ±10%

Garter Spring Outer Diameter Tolerances

- 76.20mm to 127.0mm ± 6.350mm

- 127.1mm to 190.5mm ± 9.525mm

- 190.6mm to 254.0mm ± 12.70mm

- 254.1mm to 317.5mm ± 19.05mm

- 317.6mm to 381.0mm ± 22.23mm

- 381.1mm to 508.0mm ± 25.40mm

- 508.1mm to 635.0mm ± 31.75mm

- 635.1mm to 762.0mm ± 38.10mm

Length Tolerances

- 0.0254mm to 12.700mm ± 0.381mm

- 12.701mm to 25.400mm ± 0.508mm

- 25.401mm to 50.800mm ± 0.762mm

- 50.801mm to 101.60mm ± 1.270mm

- 101.61mm to 203.20mm ± 2.362mm

- 203.21mm to 254.00mm ± 3.962mm

- 254.01mm to 381.00mm ± 6.250mm

- 381.01mm to 508.00mm ± 8.890mm

- 508.01mm to 635.00mm ± 12.70mm

- 635.01mm to 762.00mm ± 16.51mm

- 762.01mm to 889.00mm ± 20.32mm

- 889.01mm to 1016.0mm ± 25.40mm

- 1016.1mm to 1219.2mm ± 31.75mm

Rate Tolerances

Spring rate has a manufacturing tolerance of ±10%

Wire Diameter Tolerances

Note: China Spring Products Corp does not manufacture the wire used to manufacture springs.

The following tolerances apply for the following wire types:

- Hard Drawn HD A679

- Hard Drawn ASTM A227

- Music Wire ASTM A228

- Oil Tempered MB A229

- Carbon Valve A230

- Phosphor Bronze Grade A B159

- Beryllium Copper B197

- Stainless Steel 17-7 ASTM A313

- Stainless Steel 302 ASTM A313

- Stainless Steel 316 ASTM A316

- 0.1270mm to 0.4572mm ± 0.01270mm

- 0.4573mm to 1.0160mm ± 0.01524mm

- 1.0161mm to 1.5875mm ± 0.01778mm

- 1.5876mm to 2.2860mm ± 0.02032mm

- 2.2861mm to 3.1750mm ± 0.02286mm

- 3.1751mm to 6.3500mm ± 0.02540mm

- 6.3501mm to 9.5250mm ± 0.03175mm

- 9.5251mm to 12.700mm ± 0.03493mm

- 12.701mm to 15.875mm ± 0.03810mm

The following tolerances apply for the following wire types:

- Chrome Silicon A401

- 5160 H

- 2.5400mm to 3.1750mm ± 0.02286mm

- 3.1751mm to 6.3500mm ± 0.02540mm

- 6.3501mm to 9.5250mm ± 0.03175mm

- 9.5251mm to 12.700mm ± 0.03493mm

- 12.701mm to 15.875mm ± 0.03810mm

- 15.876mm to 19.050mm ± 0.04064mm

- 19.051mm to 31.750mm ± 0.04318mm

English

English