Helical Spring Design Equations

Definition: The equations needed in order to calculate the dimensions, flexibility, or strength of a helical spring design.

Helical spring design equations are the key to finding out if a spring will function the way you expect them to in your device or mechanism. These helical spring design equations will help you calculate your helical spring’s physical dimensions as well as the force and travel your spring will eject once it is in function.

There are many basic helical spring design equations to calculate your spring’s physical dimensions. You will use this to make sure that your spring will fit properly in your mechanism. These helical spring design equations are the ones provided below.

Outer Diameter Equation

If your spring is going inside a hole, you want to make sure that the outer diameter of your helical spring isn’t going to be too tight around the inside walls of the hole or even too big to fit in the hole. The equation to calculate this helical spring dimension is to multiply the wire diameter by two and add the product to the inner diameter as shown below.

2WD + ID = OD

If your spring is going inside a hole please use this "Spring Hole Clearance Guide" as a reference.

- Spring Holes .100 to .250 allow for .010 to .015 clearance

- Spring Holes .251 to .500 allow for .020 to .025 clearance

- Spring Holes .501 to .750 allow for .025 to .030 clearance

- Spring Holes .751 to 1.000 allow for .031 to .040 clearance

- Spring Holes 1.001 to 1.500 allow for .040 .050 clearance

- Spring Holes 1.501 to 2.000 allow for .050 to .075 clearance

Inner Diameter Equation

If your spring is going over a shaft or mandrel, you want to make sure that the inner diameter of your helical spring isn’t going to be too tight around the outer walls of the mandrel or shaft or even too small to fit over the shaft. The equation to calculate this helical spring dimension is to multiply the wire diameter by two and subtract it from the outer diameter as shown below.

OD – 2(WD) = ID

If your spring is going over a shaft please use this "Spring Shaft Clearance Guide" as a reference.

- Spring Shafts .100 to .250 allow for .010 to .015 clearance

- Spring Shafts .251 to .500 allow for .020 to .025 clearance

- Spring Shafts .501 to .750 allow for .025 to .030 clearance

- Spring Shafts .751 to 1.000 allow for .031 to .040 clearance

- Spring Shafts 1.001 to 1.500 allow for .040 .050 clearance

- Spring Shafts 1.501 to 2.000 allow for .050 to .075 clearance

Other basic helical spring design equations are the following

Mean Diameter

Inner Diameter + Wire Diameter = Mean DiameterID + WD = MD

Outer Diameter – Wire Diameter = Mean Diameter

OD – WD = MD

Solid Height

Wire Diameter (Total Coils) + 1 = Solid HeightWD(TC) + 1 = SH

Total Coils

Solid Height ÷ Wire Diameter – 1 = Total CoilsSH ÷ WD – 1 = TC

The previously provided helical spring design equations will help you determine if it will work when being installed. The following helical spring equations will help you calculate your spring’s working loads as well as rate. Follow these simple formulas to measure the strength and possible travel of your helical spring design.

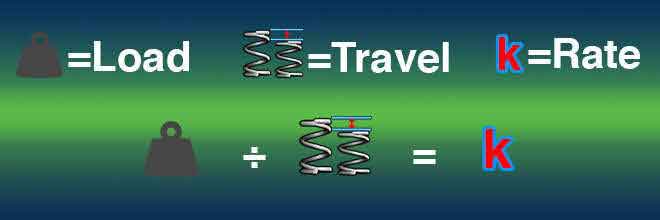

Spring Rate

Load ÷ Travel = RateL ÷ T = k

Spring Load

Rate (Travel) = LoadkT=L

Spring Travel

Load ÷ Rate = TravelL ÷ k = T

Helical Spring Rate Equation

English

English