Spring Measurements and Specifications

Spring measurements and spring specifications for compression, extension and 'torsion' springs are below.

Follow the guidelines below for the type of spring you have to determine your springs measurements and spring specifications.

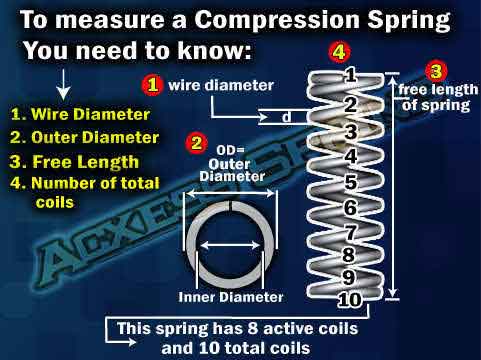

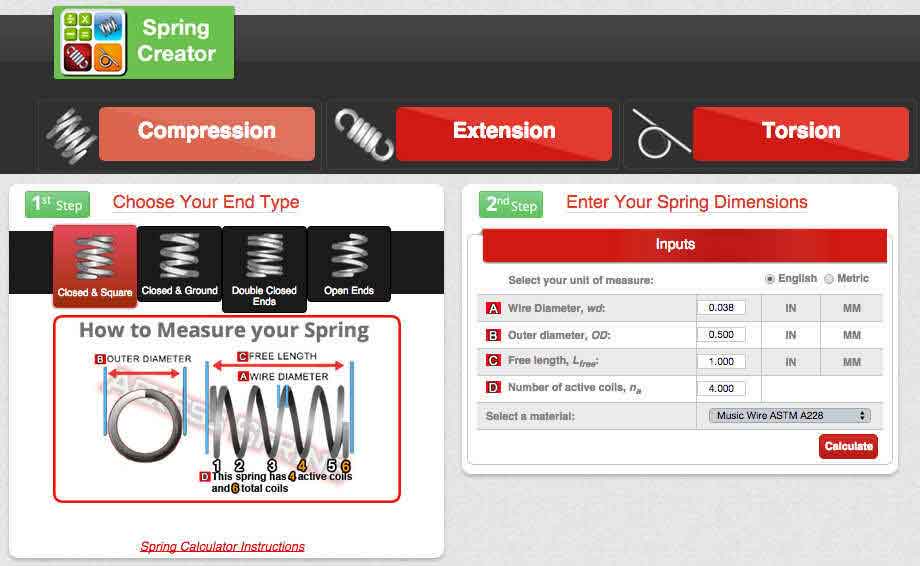

How to measure Compression Springs, Coil Springs and Helical Springs (These spring types are all the same)

To Measure your coil springs correctly See diagram to the right for explanation. ------------------------------->

You will need to know the four (4) spring specifications below:

1. Wire diameter2. Outer diameter

3. Free Length (length of spring)

4. Number of total coils

Also please choose the Spring End Type you desire:

Closed and Squared Ends

The last coil is closed touching the previous coil closed and squared ends is the most economical of all end types and works well for standing up normal size springs. Closed and squared ends do NOT work well if you have a spring with a small outer diameter you should choose closed and ground ends so it will stand up vertically straight.

Closed and Squared Ends

Closed and Ground Ends

The last coil is closed and ground flat touching with the previous coil. Closed and ground ends help the spring stand up vertically straight. This type of end lets your spring stand up straight and gives an even surface of contact to the spring base. A good choice for precision springs though a bit more costly than closed and squared ends because additional labor needs to be performed to grind the ends of the spring flat.

Closed & Ground Ends

Double Closed Ends

The last two coils on each end are closed to help stabilize the top and bottom of the spring. Double closed ends aids your springs footing especially when you have a large outer diameter coupled with a fine or smaller diameter wire when compressing or traveling to stacked height where all the coils are touching. Double closed ends help your spring ends from sliding over or slipping under the previous coil, it keeps the coils stacked up on top of each other correctly.

This is an great economical choice to prevent buckling and stabilizes your spring.

Double Closed Ends

Open Ends

The ends of the spring are open and have space or pitch in-between them. This is a good option if you need more force out of your spring but don't have the room for it. An open ended spring makes all of your coils active thus getting the all the force out it. This kind of spring end requires that you place it in hole or on a shaft to make it work. Their is usually no extra cost for this type of end thus making it an economical choice.

Open Ends

To measure your Helical Springs Rate or Spring Constant use our Spring Calculator here.

How to Measure Compression Springs Video

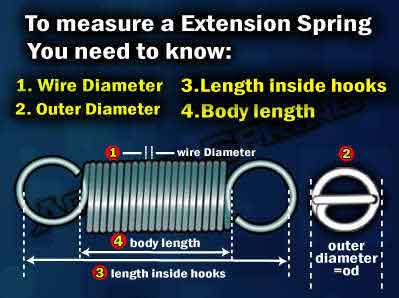

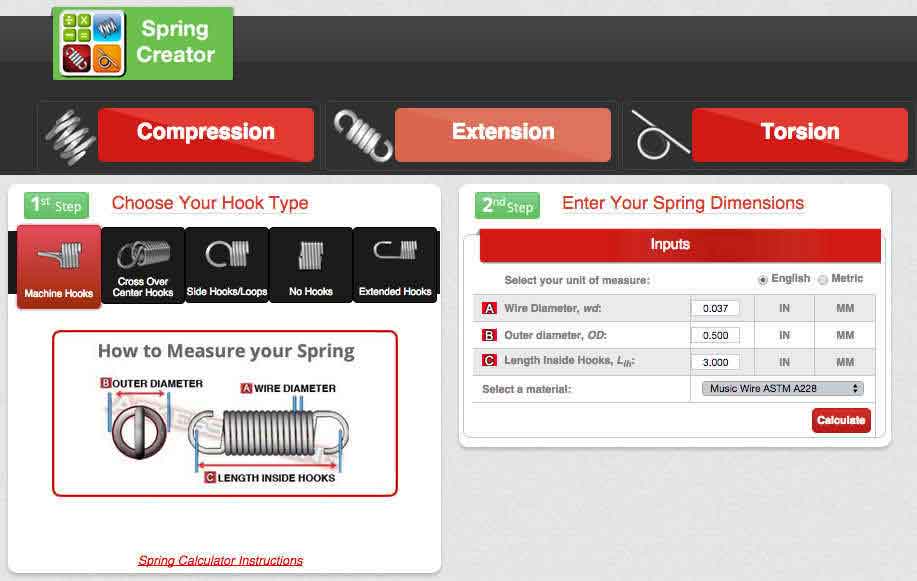

How to measure Extension Springs and Tension Springs

.To Measure your Extension Springs Correctly See diagram to the right for explanation. ---------------------------------->

You will need to know the following extension spring measurements:

1. Wire Diameter 2. Outer Diameter 3. Length inside Hook 4. Body Length 5. Choose your hook type below:

Choose from the different hook types below:

Machine Hook

A good standard hook choice for commercial springs. This hook is made from the end coils on the spring by bending it out to create this hook. Machine hooks should not be stretched over their limit to avoid breakage.

Machine hooks

Cross Over Center Hook

A great standard hook choice for precision springs and commercial springs. This type of hook is made from the end coils of the spring but is bent straight down the center of the spring, it then loops around to create the round hook. This is a more stable hook than the machine hook for the same price.

Crossover center hooks

Side Hooks

The most economical of all hooks is the side hook.

This hook is made from the end coils. It is bent outwards from the side of the spring to create the side hooks. This is a good hook for an commercial or everyday spring which doesn't have to be precise.

Side hooks

No Hooks

This type of no hook spring is very useful when inserting a bolt down through the inner diameter so to anchor the spring ends. The ends of the spring act as threading onto the threads of the bolt thus securing the ends. This type of fastening or connecting has tremendous benefits especially when dealing with broken hooks that cause a user to purchase extension springs repeatedly.

Fastening the spring to a bolt or a thread offers superior strength versus any other hook type and is the most economical to manufacture.

No hooks

Extended Hooks

This is a good hook that is used when having to get around an object to engage the hook too. It offers the user a way to get the hooks fastened by extending the length of the hook to reach into the area where one will attached the hook. Extended hooks can be made with larger or smaller diameters than the extension springs normal outer body diameter. This type of hook is the most costly but can really make the difference when installing an extension spring where no other hook will work.

Extended hooks

To measure your Extension Springs Rate or Extension Spring Constant use our extension spring calculator here.

How to Measure Extension Springs Video

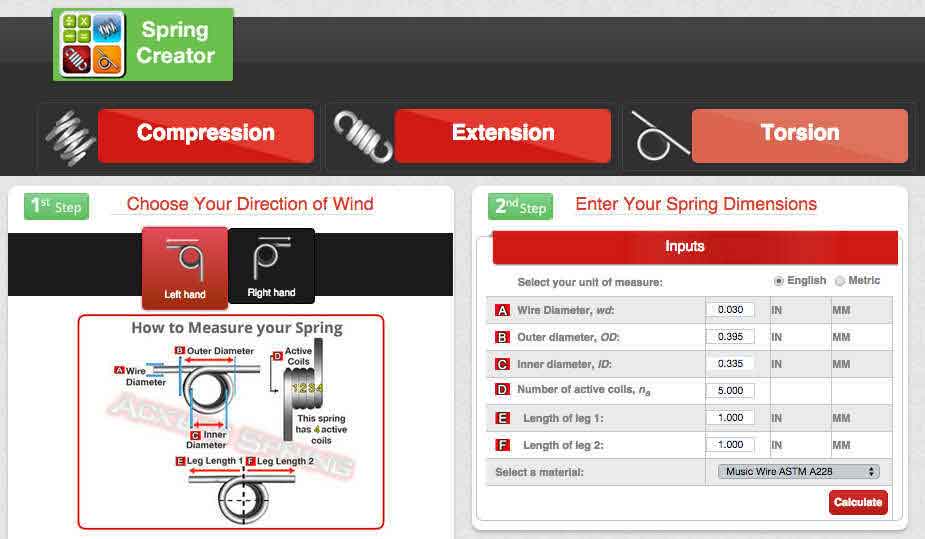

How to measure Torsion Springs:

To Measure your Torsion Springs correctly you need to know the following torsion spring dimensions:

See diagram to the right for explanation. ----------------------------------->

1. Choose your direction of wind: Left hand or right handPlease see diagram to the right to determine if your spring is Left hand or Right hand.

2. Wire diameter3. Outer diameter

4. Number of total coils

5. Length of leg 1

6. Length of leg 2

If your spring has any bends or shapes on the legs please let us know.

To measure your Torsion Springs Rate or Torsion Spring Constant use our torsion spring calculator here.

Español

Español