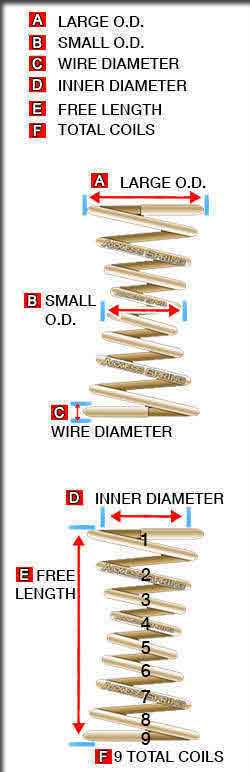

Barrel Springs Nomenclature

Definition: Barrel springs are compression springs which are helically coiled round wires forming a convex or concave shape. They are used to provide balance and reduce the solid height.

Note: Click on the highlighted titles to learn more.

Concave

The hourglass/barbell shape some barrel springs may have due to the ends having larger diameters than the middle coils.

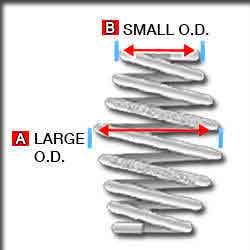

Convex

The opposite of a concave barrel spring. Convex barrel springs look like a barrel because the end coil diameters are smaller than the diameter of the middle coils.

Wire Diameter (WD)

The thickness of the round wire which the compression spring is made of.

Large Outer Diameter

The thickness of the largest coil in the barrel compression spring’s body.

Small Outer Diameter

The thickness of the smallest coil in the barrel coil spring’s body.

Inner Diameter (ID)

The width of the inside of the smallest coil. Calculate by subtracting two wire diameters from the small outer diameter.

Mean Diameter (MD)

The medium or intermediate diameter that is located right in the middle of inner diameter and outer diameter. Calculate by subtracting one wire diameter from the outer diameter or by adding one wire diameter to the inner diameter.

Free Length (FL)

The free, unloaded length of a barrel spring.

Total Coils (T/C)

The total amount of coils including open and closed coils.

Active Coils (A/C)

The open/active coils in your barrel spring. You may calculate the active coils by subtracting the closed coils from the total coils.

Solid Height (LH)

The length/height of your spring when it is fully compressed and all of the coils are touching.

Spring Pitch (P)

The distance between your spring’s coils.

Rise Angle of Coils

Because, there is pitch in between the coils, the wire which the coils are made of rises. This is the measurement of how much the angle of the coil is raised.

Index (I)

The proportional ratio between your spring’s wire diameter and mean diameter (measured from both the small and large outer diameters). It specifies the tightness of your barrel compression spring’s coils and the level of manufacturing difficulty.

Loaded Height (LH)

The compressed length/height of your tapered spring when a load has been placed on it.

Telescope (Nesting)

When the barrel spring’s coils perform a telescope effect when being compressed due to the different diameters. The smaller diameter from the top compresses into the next coil’s inner diameter and so on.

Travel (F)

The motion in which a barrel compression spring is compressed. The distance traveled is the difference between the free length and the loaded height.

Load (P)

The force being applied on the spring in order for it to travel.

Maximum Travel Considering Solid Height (Max F)

The maximum travel your barrel spring is able to achieve considering its solid height as to not exceed it.

Maximum Load Considering Solid Height (Max P)

The maximum load your spring can withstand considering its solid height as to not exceed it.

Closed Ends

Closed coils without any pitch in it at the edges of the barrel compression springs. (first and/or last coils)

Closed and Ground Ends

Closed coils without any pitch in it at the edges of the barrel springs which are ground to help the spring stand straight on a flat surface. (first and/or last coils)

Double Closed Ends

Two closed coils without any pitch in it at the edges of the springs. (first and/or last coils)

Open Ends

All coils of the spring have pitch in between them, including the edges.

Endurance Limit

Maximum stress at which your barrel spring will perform indefinitely without failure for a given minimum stress limit.

Permanent Set

The product of exceeding the elastic properties of a barrel spring thus keeping it from returning to its original free length once the load has been released.

Concave Barrel Springs Physical Dimensions Nomenclature

Convex Barrel Springs Physical Dimensions Nomenclature

Español

Español