Extension Spring Hook Types

Definition: The ends of a tension or extension spring which form a hook, loop or radius.

Extension springs have hooks because their function is for their coils to be pulled apart. These hooks will be connected to certain components that are to be involved in cycles of pulling on the tension spring and returning to its free, pre-loaded or unloaded state.

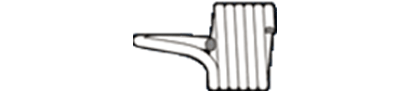

Machine Hooks: Machine hooks are one of the two most commonly used type of hooks. These hooks are used in most applications and are stronger than cross over center hooks because the radius of the bend to make the hook is not as pronounced. They are made by bending ¾ of a coil out.

Cross Over Center Hooks: This is the second most commonly used type of hooks. The radiuses of the bends needed to make the type of hook are more pronounced. This type of hooks is made by lifting the last coil (like side hooks) and twisting the coil towards the middle therefore crossing the center.

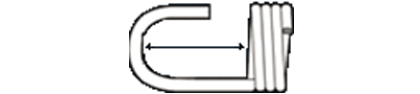

Side Hooks: These are needed when the body of the spring must not interfere with the components of a mechanism. This is due to the fact that the hooks are on one side of your spring therefore the other side of the spring is offset. They are made by simply bending the last coil out so they are more economical than cross over center hooks.

Extended Hooks: The function or use of extended hooks is very similar to that of a side hook. These are also very useful when you need a long length inside hooks but a short body length to get more force out of your spring through less coils. It is the most expensive hook type.

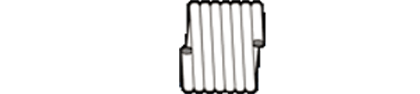

No Hooks: Offer a great advantage over hooks by having NO stress or fatigue on the ends of the spring as well as being the most economical extension spring to manufacture. The amount of pulling force and distance increases as well as the cycles of life on the spring are greatly increased. No hooks gives you the ability to use a bolt to thread into the inner diameter of the extension or tension spring thus securing the ends of the spring.

Español

Español