Extension Spring Calculations

Definition of Extension Spring Calculations:

The process of calculating the shear modulus of a spring wire, young's modulus of spring wire, poission's ratio for spring wire along with a springs wire diameter, mean diameter and number of active coils to obtain an extension spring calculation.

Here is an easier and faster way to calculate your extension spring calculations by using our free online spring calculator; which provides you with a full extension spring calculation and analysis of your spring. Just enter a few of your extension spring's dimensions, and you'll obtain the spring calculation needed. You will get all the information you need to make sure your spring will function correctly in your application.

Basic Extension Spring Calculation Formulas

Sometimes, you might only have a few of your extension spring's dimensions but in order to calculate other things such as rate and travel, you'll need to know a bit more. Here you will see a couple examples of different scenarios where a certain spring dimension is needed.

To Calculate Wire Diameter From a Spring:

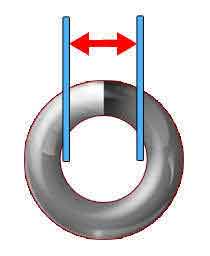

If you only have your Outer Diameter (OD) and Inner Diameter (ID) but need Wire Diameter (WD), you must subtract your Inner Diameter (ID) from your Outer Diameter (OD) and then divide the result by two as shown in the formula below:

(Outer Diameter – Inner Diameter) ÷ 2 = Wire DIameter(OD - ID) ÷ 2 = WD

To Calculate Your Spring's Outer Diameter From Inner Diameter

Multiply your Wire Diameter by two and then add it to your Inner Diameter; as shown in the formula below:

2 * Wire Diameter + Inner Diameter = Outer Diameter2WD + ID = OD

To Calculate Your Spring's Inner Diameter From Outer Diameter

Multiply your wire diameter by two and then subtract the result from your Outer Diameter; as shown in the following formula:

Outer Diameter – 2 * Wire Diameter = Inner DiameterOD – 2WD = ID

To Calculate Your Spring's Mean Diameter

This specific dimension is calculated by taking one wire diameter and subtracting it from your compression spring's outer diameter or adding one wire diameter to the inner diameter as shown below:

Outer Diameter – Wire Diameter = Mean DiameterOD – WD = MD

Inner Diameter + Wire Diameter = Mean Diameter

ID + WD = MD

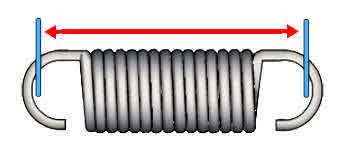

To Calculate an Extension Spring's Length Inside Hooks from Body Length (Using Machine Hooks)

Multiply 3/4 or (75%) of the Inner Diameter by two and add the result to the Body Length (BL):

3/4 Inner Diameter * 2 + Body Length = Length Inside Hooks3/4 ID * 2 + BL = LIH

To Calculate an Extension Spring's Body Length from Length Inside Hooks (Using Machine Hooks)

Multiply 3/4 or (75%) of the Inner Diameter of your extensions spring and subtract it from the Length Inside Hooks (LIH):

Length Inside Hooks – (3/4 Inner Diameter x 2) = Body LengthLIH – (3/4 ID x 2) = BL

To Calculate an Extension Spring's Length Inside Hooks from Body Length (Using Cross-Over Hooks)

Multiply Inner Diameter of your extension spring by two and add it to the Body Length (BL):

2 x Inner Diameter + Body Length = Length Inside Hooks2 ID + BL = LIH

To Calculate Total Coils From Body Length

Divide Body Length by Wire diameter and subtract 1 wire diameter:

Body Length ÷ Wire Diameter – 1 wire diameter = Total CoilsBL ÷ WD - WD = TC

To Calculate Your Extension Spring's Index

This spring calculation is needed to make sure that the spring you require is manufacturable. You must divide your mean diameter by your wire diameter as displayed in the following spring index formula:

Mean Diameter ÷ Wire DIameter = IndexMD ÷ WD = I

Advanced Extension Spring Calculations

The next step to designing your extension spring is making sure that the dimensions you already have give you a spring rate that will work with the loads you plan to apply to your extension spring as well as travel. Here we will show you how to get to these extension spring calculations.

To Calculate Extension Spring Constant K / Rate

Calculating your extension spring's rate is no easy task since you have to keep many things in mind. We have provided the spring calculation for an extension spring constant K or rate below in order to obtain an extension spring calculation.

G = E/2(1 + V)

d = D outer - d

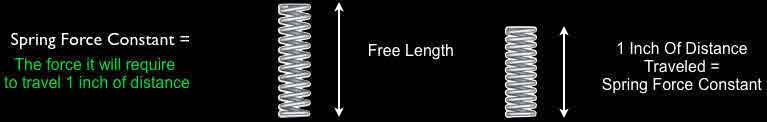

If Spring constant is 1 LBF/inch

it takes 1 lb of force to travel 1 inch of distance

1 LBF/INCH= 1LB of force per 1 inch of travel distance

Meaning of Variables in Above Formulas

- G = Shear modulus of material

- d = Spring wire diameter

- D = Outer diameter of spring

- na = number of active coils

- E = Young's modulus of material

- V = Poisson's ratio of material

How to Calculate Your Extension Spring's Load

Multiply your spring's Rate (R) by the distance you expect your spring to travel (DT) as shown below.

Rate * Distance Traveled = LoadR*DT=L

Next add the initial tension to this to get your true load at a distance traveled

How to Calculate Your Extension Spring's Initial Tension

Initial tension is the force/tension sandwiched in between your extension spring coils before even being extended. This initial tension spring calculation is calculated as the formula below shows.

Load = Stress * Wire Diameter ^ 3 ÷ 2.55 * Mean Diameter = Load in LbsP = Sd^3 ÷ 2.55D = Load in lbs

Meaning of Variables in Formulas

- d = Wire size

- D = Mean Diameter

- N = Number of active coils

- Rf = Rate of extension spring (in lbs./inch)

- S = Stress (lbs. /Sq. Inch)

- P = Load (lbs)

- M = Moment (inch-lbs.)

- D / d = Index correction (developed from Wahl Factor)

How to Calculate Your Extension Spring's Distance Traveled:

Divide the Load (L) you will be applying to your spring by your spring's Rate (R) as shown in the following formula:

Load ÷ Rate = Distance TraveledL ÷ R = DT

How to Calculate Your Extension Spring's Rate From Load and Travel:

In case that you aren't able to calculate your spring's rate with the formula previously provided but you know how much load you plan to apply on your spring in order for it to travel a certain distance, you must divide the load by the distance your spring will travel as displayed on the formula below.

Load ÷ Distance Traveled = RateL ÷ DT = R

Español

Español