Helical Spring Calculations

Definition: The action of calculating a helical spring’s dimensions and specifications through several formulas and equations.

There is a step by step process when generating a helical spring’s calculation using our online spring calculator, Spring Creator. Following the calculator provided below, you will see the step by step process of generating your helical spring calculations in case you may need any assistance.

Step 1.) Enter your helical spring's dimensions

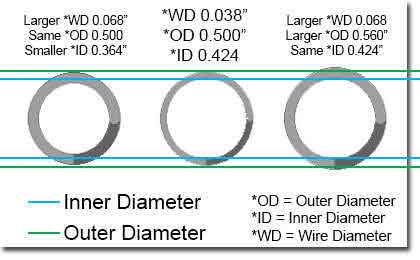

When working on a spring design, the first thing you must do is measure your spring’s surroundings to make sure that your spring will fit correctly when being installed. If it is going over a shaft, make sure you have a few thousandths of an inch of clearance between the shaft and the helical spring’s inner diameter so that you avoid friction when the spring is traveling down. The same goes for your spring’s outer diameter if it is being installed inside a hole or if there are other parts in your mechanism around it. Make sure that there is some clearance between the helical spring’s outer diameter and its surroundings. Keep in mind that adjusting the wire diameter will affect the coil diameters as well. The diameters will either increase by two thousandths of an inch or decrease by two thousandths of an inch if you increase or decrease the wire diameter by one thousandths of an inch. This means it will increase or decrease double the quantity of adjustment.

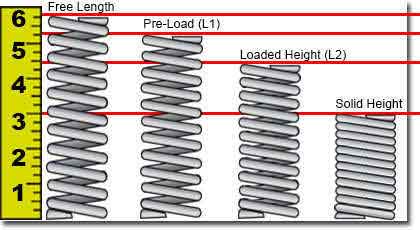

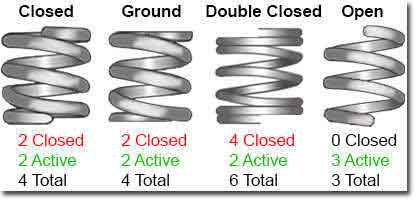

The free length must be measured from the distance between the “ground” where the spring will be standing and the part of the mechanism that will be applying the load to compress the spring. It is recommended that you add a few more thousandths of an inch so that you generate preload for the spring to stay in its place. For the total coils, you must consider the solid height because you must make sure you will be able to meet your loaded height. The difference between the two is that the solid height is the height of your helical spring’s coils when they are fully compressed and the loaded height is the height you require for the spring to have after you’ve applied a load to fulfill a certain distance traveled according to your helical spring’s rate. Your spring’s end type is also considered in this calculation and the active coils will be affected by it.

The most common type of ends are closed and squared ends. With closed ends, your helical spring’s total coils will be two more than the active coils since the coils on the ends are closed thus not active. In the case of double closed ends, your helical spring will have 4 total coils more than the active coils. When it comes to closed and ground ends, it works the same way except you will subtract one wire diameter from the solid height since you’re taking out half a wire diameter from each end when they’re ground. Only when you have open ends are the spring’s total coils and active coils the same. In the examples to the right you will see the helical spring calculations explained in this text.

Dimension Formulas and Diagrams

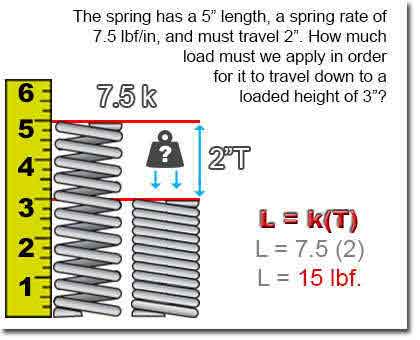

Step 2.) Working Loads, Travel, and Rate

The next step is to figure out how much load will be placed on your spring and how much it is supposed to travel under that load to meet your required loaded height. This is known as a working load. Sometimes you may have more than one and that is where you do L1 and L2 calculations. Knowing your spring’s working loads will help you calculate the required spring rate that will make your helical spring meet them. Spring rate is measured in pounds per inch. That is pounds of force per inch of travel. This means that the load will depend on the amount of inches you travel and the distance traveled will depend on the load being placed. It is all proportional and accumulative when it comes to spring rate. It is what defines your helical spring’s strength/stiffness. You may compare it to your car’s speedometer and how the speed is measured in miles per hour; meaning the amount of hours you drive is proportional to the distance traveled and vice versa.

The helical spring calculations to calculate both rate, and your working loads (either distance traveled or load) are provided to the right along with the spring rate diagram.

Formulas and Diagrams

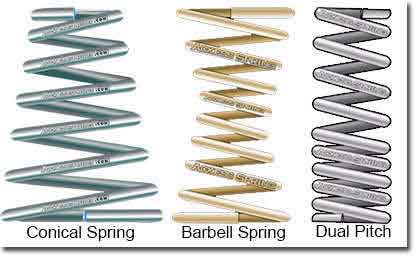

Step 3.) Additional

The information previously mentioned are the essentials of making a spring design. There are other factors taken into note as well such as the material type or custom modifications such as bends, dual pitch, or changing diameters. Our helical spring calculator provides you with several different material types which can serve your helical spring for many applications but the most common are Music Wire ASTM A228 ad Stainless Steel 302 A313. Music Wire is the most economical and is used when your spring isn’t required to undergo extreme temperatures or corrosive environments. Stainless Steel 302, on the other hand, is a more resistant type of material which will resist corrosion and higher temperatures than Music Wire will. The other customizations are not provided on our helical spring calculator but our engineers will be more than glad to help you in designing the ideal spring for your mechanism so don’t hesitate to contact us.

Custom Helical Springs

Español

Español