Presetting Springs

Today we will be addressing some of the most common questions about presetting springs and the process behind this.

What is presetting?

Presetting is the act of taking a compression spring, putting it over a shaft and compressing it all the way down to where the coils touch and you cannot go anymore (solid height) . This takes any fatigue or stress off the spring.

To better get a visual of this, let’s say a spring is two inches long (that is called the free length) and the design does not allow you to go all the way down to solid height (let’s say solid height is ¼ inch for this example) and you need an inch of travel but in this example, the design was not built for you to have an inch of travel and was only made for you to have ¾ of an inch as the max safe travel .

If you were to force the spring to still go down all the way to an inch it might take a set at a quarter inch or an eight of an inch, it just depends on the design.

The art of presetting is to take that set out. That is, to eliminate that possibility of it setting and any kind of shortening of the free length would be taken away by presetting the part. This of course would also mean that the spring would now have a different free length.

What Type of Springs Can Be Preset?

You can preset a compression spring, a conical compression, barrel springs, hourglass springs and a torsion springs. You cannot pre-set an extension spring because its function is made to stretch not compress, therefore they are unable to take a set. Compression springs are the most common type of springs that are pre-set.

When Can Presetting Be Done?

Presetting is usually required when you need more travel from a spring but the current design does not allow that to be completed adequately. The issue usually arises when someone has manufactured a device or space for a spring without consulting a spring engineer that can further advise on how much space is needed to meet all the necessary requirements and accomplish the job adequately.

Let’s give you an example.

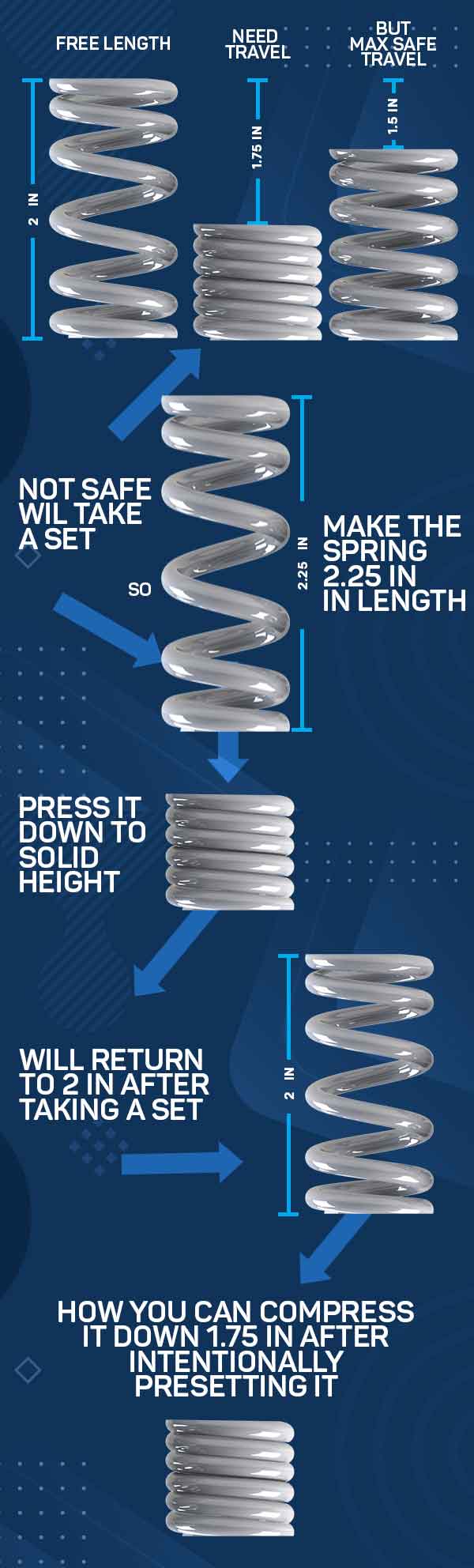

Let’s say you have a two inch long spring and you need an 1.75 inch of travel but the max safe travel is 1.5in even though the solid height is a quarter inch. In theory people think that you would be able to go an 1.75 inch down of travel. Hower if that design does not allow you to go an inch and three quarters. Let’s say it only allows you to go an inch and a half as the max safe travel, and you are a quarter inch away you may be able to pre-set it using reverse engineering.

How this works is that instead of manufacturing it to be 2 inches long you would make it 2 ¼ inches long so the difference is ¼ inch in length and then preset it to solid height it would take a set at a ¼ inch and returns to be two inches long and can give you the travel you need. The spring took a set pretty much means that the spring shrunk. However, now you are able to have it travel further down and keep the length at 2 inch.

Español

Español