Spring Design Help

China Spring Products Corp gives the user a large amount of technical information through various spring design help articles throughout their website. Also included, is our famous spring calculator, Spring Creator where you can create a compression, extension, or torsion spring design along with a full spring analysis and live blueprint. Many people are not aware of the several factors that take place when it comes to spring design. The following information and provided links will direct you towards designing the most perfectly working spring your device needs.

Compression Spring Design Help

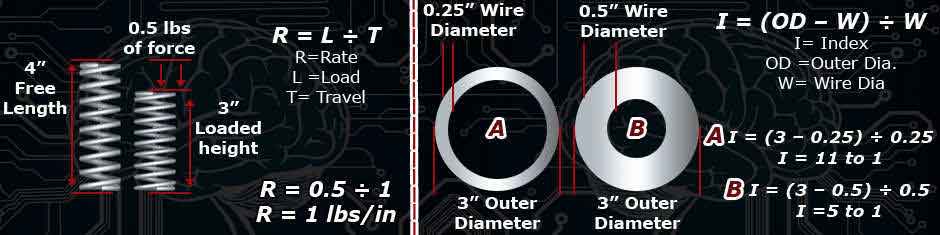

Compression springs are the most common, popular, and usually the most economical springs on the market. They are also the easiest to design; but this doesn’t mean that you don’t have to be aware of the important factors behind your compression spring design. In compression spring design help you must be aware of the amount of travel your compression spring must compress to and the amount of load you’ll be placing on your spring for it to travel down to the desired loaded height. Once you are aware of these values, you will be able to calculate the spring rate or spring constant you need your spring to have by simply dividing the amount of force by the distance traveled as the formula in the image below indicates. Sometimes, you might reach the perfect amount of rate but won’t be able to travel down to the desired loaded height due to your spring’s fatigue limit which takes into consideration spring index. This is where “maximum safe travel considering solid height” or “maximum spring compression” comes in as well as “maximum safe load considering solid height”. If your spring has too small of an index or if your spring’s solid height is greater than the loaded height you wish to achieve, you will not be able to achieve the travel or load you wish to apply so keep these factors in mind. Spring index is tightness of the diameter of the coils of your spring. The formula and explanation for index are also shown in the image below.

Spring Rate and Spring Index Diagram

Extension Spring Design Help

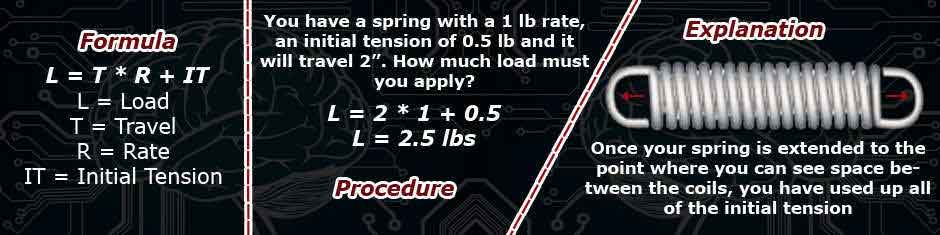

Extension springs are also very common but they aren’t as economical as compression springs due to the fact that these will usually have hooks. In extension spring design help, the process is similar to that of a compression spring. You still have to take into mind its physical dimensions as well as the extended length you wish your spring to travel too and under what amount of load. Extension spring rate is calculated the same way but there is one extra factor you have to take into mind besides rate. You see, extension springs already have a collected amount of energy before being extended. This huddled energy is called initial tension. So when you extend your spring, you will apply the force indicated by the calculation of rate plus the amount of initial tension. Initial tension does not increase in a linear motion like rate does, it is only added once whether you travel one or two inches. The image below provides the formulas and explanation of this operation. The limitations like maximum safe travel considering hook stress and maximum safe load considering hook stress are also a critical part of your design. Missing these important values can eventually cause the hooks of your spring to break. Spring index for extension springs is the same as it is for compression springs or any other spring so make sure your index is no less than 4 to 1 so it won't be that tight so that your spring is able to travel your required distance traveled freely.

Initial Tension Diagram

Torsion Spring Technology

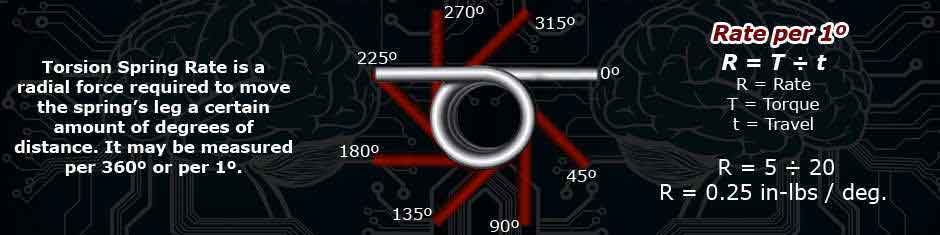

Torsion springs are somewhat popular and may be more cost effective than extension springs as long as they don’t have any bends on the legs. Torsion spring design help is quite different from the previously mentioned types of springs because we are now dealing with a radial force. You will no longer be traveling inches or millimeters but degrees of deflection and your torsion spring’s rate will now be measured in inch-pounds per degree or inch-pounds per 360 degrees. You will also have to look out for the “maximum load possible” and the “maximum safe travel” to make sure your spring functions as expected. When your spring deflects, the inner diameter contracts or decreases in size, so be sure that this measurement will not be smaller than the diameter of your shaft or mandrel.

Torsion Spring Rate Diagram

Español

Español