Spring Makers

Definition:

Persons or Companies who work in the production of coil springs such as compression springs, extension springs, torsion springs, conical springs, garter springs, barrel springs, magazine springs, and gun springs.

Spring makers work on lathes or automatized CNC spring machines. China Spring Products Corp manufactures their springs on CNC machines. These are worked on by highly experienced spring technicians. In order to start the production of each spring, they are provided with spring specifications along with a blueprint indicating the tolerances the customer specified as well as material type. Spring makers at times may need to perform secondary operations such as bends (on torsion spring designs), hooks (on extension spring designs), or grinding (on compression spring designs). Our manufacturing capabilities go from micro wire diameters like 0.006” to large wire diameters like 1.000”.

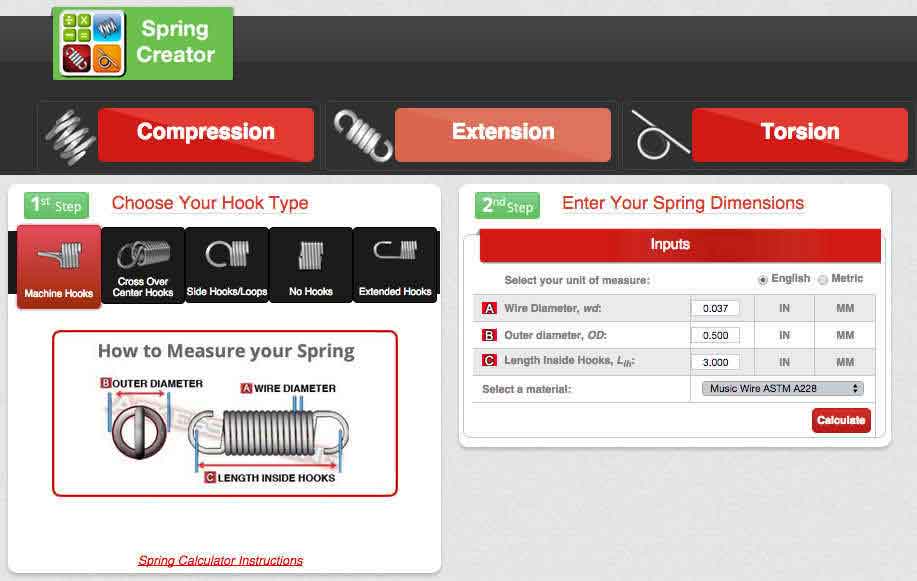

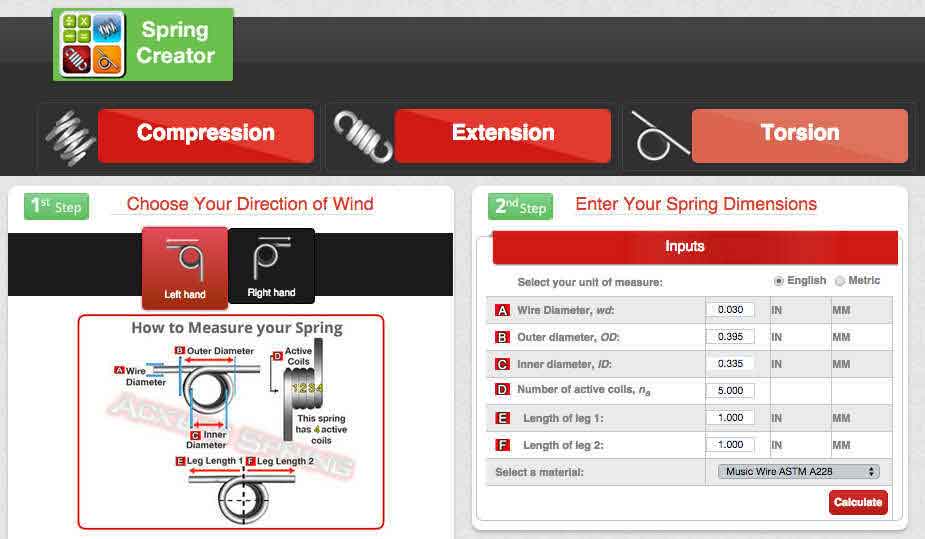

Design your spring using our spring maker software, Spring Creator. Here you are able to design compression, extension, or torsion springs. Calculate your spring’s physical dimensions as well as its load and travel capacities. Also, receive a full spring analysis containing all this information along with a live blueprint of your spring design. But before going on to doing your design, learn the basic spring design steps specified below.

Step 1.

What Material is Best For Your Design?

Knowing what material will resist your application's environment and which is the most economical choice can be tricky. Visit our “Properties of Common Spring Materials” page for information on which wire type will be best for your application. We offer many variations of spring wires. These are listed below:

- Music Wire

- Chrome Silicon

- Stainless Steel 316

- Stainless Steel 302

- Stainless Steel 17-7

- Phosphor Bronze

- Hard Drawn

- Beryllium Copper

- Oil Tempered

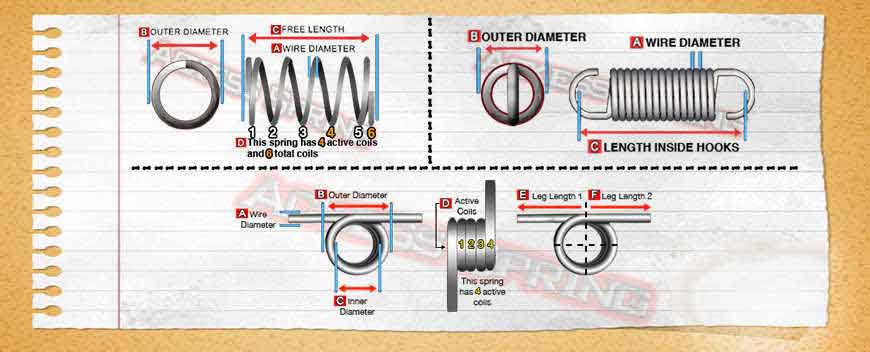

How to Measure Diagrams for Spring Makers:Compression, Extension and Torsion Springs

Step 2.

What Tolerances Should Your Design Have for its Physical Dimensions?

To know what physical tolerances your spring should have you must measure the parameters in which the spring will go into. Whether it is in a hole, over a shaft (mandrel), or both. Once you have measured these parameters you will know what restrictions you may have when it comes to your spring’s outer and inner diameters. Your spring’s free length also has a lot to do with its functionality on your device. If it is too long, your load may not be able to travel down to the desired loaded height because more travel implicates more force.

Standard Spring Tolerances

| Outer and Inner Diameter Tolerances | |

| Diameter | Tolerance |

| 0.051 to 0.075 | +/– 0.003 |

| 0.076 to 0.113 | +/– 0.004 |

| 0.114 to 0.240 | +/– 0.005 |

| 0.241 to 0.500 | +/– 0.008 |

| 0.501 to 1.000 | +/– 0.015 |

| 1.001 to 1.225 | +/– 0.020 |

| 1.226 to 1.460 | +/– 0.030 |

| 1.461 to 2.000 | +/– 0.040 |

| Free Length Tolerances | |

| Free Length | Tolerance |

| 0.001 to 0.500 | +/– 0.020 |

| 0.501 to 1.000 | +/– 0.025 |

| 1.001 to 2.000 | +/– 0.035 |

| 2.001 to 4.000 | +/– 0.075 |

| 4.001 to 8.000 | +/– 0.125 |

| 8.001 to 10.000 | +/– 0.175 |

Step 3.

Use Spring Creator to Design Your Spring

Now that you have what material type to use and the physical restrictions, you can go ahead and start designing your spring. Input dimensions into our spring calculator which are inside of the tolerances. Make adjustments as you go to meet your desired loads and rate. Once you’re done, click on “generate blueprint” to generate a real-time blueprint of your design along with your spring’s analysis. START NOW!.

Do you wish for your springs to be plated? No problem! We offer various plating types such as zinc (black, blue, clear or gold), black oxide (with or without wax), nickel plating, gold plating, phosphate or manganese coating.

Español

Español