Torsion Springs Calculator

Definition:

Torsion spring design software used to calculate and generate a torsion spring design giving you torsion spring rate, maximum safe travel in degrees, maximum spring torque and many more torsion spring specifications which are critical to your torsion spring’s functionality. It will also generate a live blueprint along with a full torsion spring analysis.

Get our New Free Spring Creator App for Android and iOS Devices

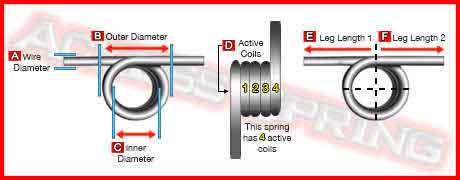

At China Spring Products Corp, we have made designing your torsion springs fast and easy. Other torsion spring calculators will usually ask you to input information that our calculator automatically calculates for you like torsion spring rate or constant. With our torsion spring calculator, Spring Creator, you are only required to enter a few of your torsion spring’s physical dimensions such as direction of wind, wire diameter, outer diameter, active coils, and material type.

Besides our spring calculator, China Spring Products Corp specializes in helping its customers get just the right design so feel free to give us a call and we will gladly help you reach the perfect torsion spring design. Below you will see what design specification we will usually ask you for in order to reach the most adequate torsion spring design.

What type of environment will your spring have to resist?

This is one of the most important steps to designing your spring because not only does your spring have to meet certain loads, but it has to be able to last in your application. You cannot use a music wire torsion spring in a corrosive environment; it will rust. Also you must be aware of the temperatures that will be around it, whether it is a corrosive or moist environment, or if in needs to be non-magnetic.

The most common and economical spring material is music wire. If your spring doesn’t have to resist any harsh environments, this would be the best wire type to use. In case it has to resist corrosive environments we recommend using stainless steel 302 which is the most common and economical type of stainless steel. If you need a high temperature wire we recommend 17-7 stainless steel which will withstand up to 800 degrees fahrenheit. When you need your torsion springs to be non-magnetic, we will recommend you use stainless steel 316. But you should know that stainless steel 316 is only 90% non-magnetic. This is due to the process the metal undergoes when it is being produced into spring wire.

What physical parameters will your torsion spring be associated with?

Torsion springs will usually go over a shaft or arbor so this will the the first dimension that must be taken into account. We need to know the shaft’s diameter to make sure the torsion spring will not be too tight around it; especially because once a torque is applied to the spring, its inner diameter will shrink. You must also make sure that the overall outer diameter and legs will fit so, to mark size restrictions, we’ll have to know the measurements of the torison spring’s surroundings.

Torsion Spring Physical Dimensions

What amount of torque will be applied to your spring?

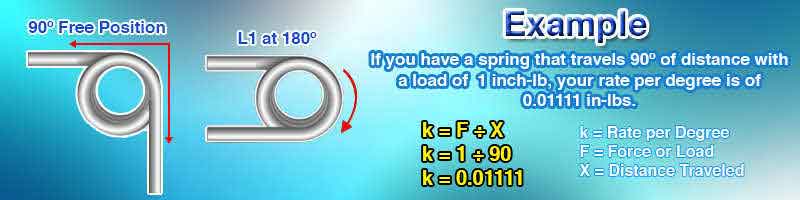

Now we get into the calculation part of your torsion spring design. Our torsion spring calculator will calculate your torsion spring’s rate. Knowing the rate of your torsion spring design will help you calculate your spring’s torque at the amount of degrees you need to travel. Therefore, letting you know whether you are meeting your required amount of torque or if you need to make any adjustments in order to get more or less force.

Español

Español